R&D Focus

RoftSIM to Replace Traditional Induction Motors

Video of RoftSIM.

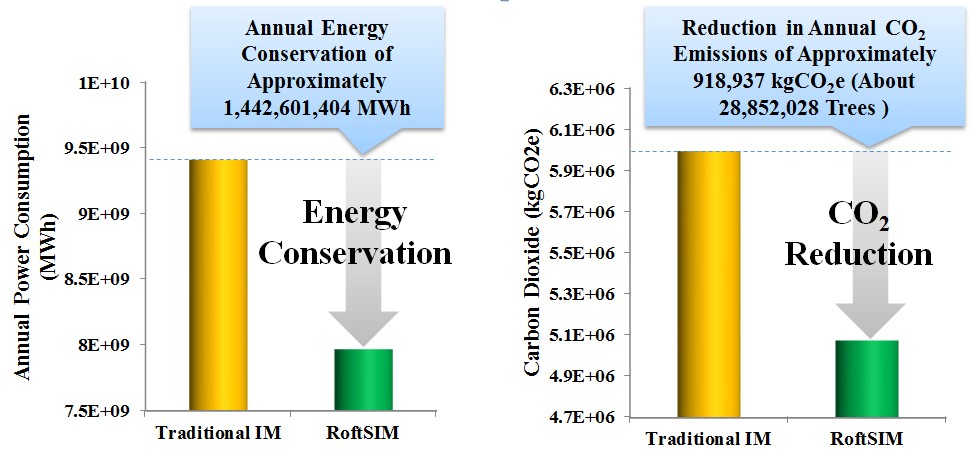

The induction motor has remained unchanged since its inception more than a century ago by Nikola Tesla. It has become our main industrial workhorse due to its simplicity in construction and low cost. However, because the induction motor is used widely on a global scale, it contributes to a significant amount of power consumption. As energy conservation becomes a focus for major industrialized countries, constant efforts have been made to improve traditional induction motors.

ITRI’s RoftSIM improves the efficiency of traditional induction motors.

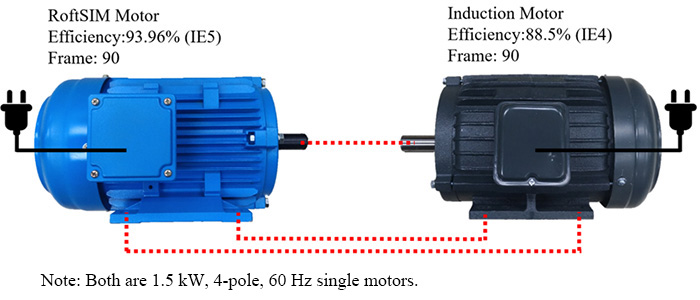

The Rotor Flux Tailoring Syncing Induction Motor (RoftSIM) is ITRI’s effort in improving the efficiency of traditional induction motors. It possesses the ability to switch from an asynchronous mode to a synchronous mode and can operate at an IE5+ class efficiency without overly sacrificing the original beneficial characteristics of an induction motor. This is done by making changes to the construction of a traditional induction motor. Reluctance-Units are incorporated, where patterned openings are punched into the silicon lamination layer, which then confines the magnetic flux to the fixed channel.

The primary goal of the RoftSIM is to replace existing induction motors, which are used in various industrial applications. It aims to provide an improved efficiency and operating flexibility, whether operating directly on the line, such as in most industrial applications, or driven by an inverter, such as in electric vehicles. Apart from replacing traditional induction motors, it can be used in situations where a synchronous rotation is required without the need of a driver, or can apply to an inverter for variable speed drives.

Efficiency Comparison of RoftSIM and a traditional induction motor in the same frame size.

The improved efficiency of the RoftSIM comes from the reduction in rotor copper loss and is expected to greatly reduce our carbon footprint. It will impact industrial motor use, as single and driverless applications account for 77% of all industrial motor use. Once it successfully replaces all traditional induction motors, it is estimated to generate more than 1.4 billion MWh in annual savings. Furthermore, the RoftSIM has a low production cost, as the minor changes in the rotor lamination patterning have no additional cost.

Expected energy saving and carbon reduction benefits from the RoftSIM.

Compared to other existing products, the main improvements of the RoftSIM are the ability to operate both asynchronously and synchronously, the ability to line-start, and the reduction of complexity as it does not require a magnet. The low production cost and improved efficiency of the RoftSIM make it a suitable replacement for traditional induction motors.