R&D Focus

Prognostic and Health Management Software in Semiconductors

Video of PHM.

Fault prognosis for semiconductor manufacturing has been developed for over 20 years, but the prediction accuracy has not met the requirements of manufacturers and application extension is difficult. Therefore, when a malfunction occurs during operation, the industry still relies on the experience of equipment engineers to identify the source of the problem, which takes time and may influence production capacity and quality. ITRI’s Prognostic and Health Management Software in Semiconductors (PHM) uses ensemble learning technology to create a successful fault prognosis system for the semiconductor industry.

PHM provides accurate prognosis that can predict upcoming equipment failure.

PHM is capable of predicting which hardware component or software indicator will encounter a fault in the coming period of time, giving the technician or engineer enough time to eliminate problems and take corrective measures before damage is done. This helps avoid loss caused by sudden failures and can effectively ensure product quality especially for high-mix, low-volume operation. Consequently, scheduling maintenance, material preparation, and labor deployment all become much easier.

The high-precision software was also used in abnormality detection of semiconductor equipment of a top 5 mobile memory chip supplier in the world, Winbond. The technology was also transferred to Marketech International Corp. (MIC). PHM also has high scalability, without restriction to specific facilities. In addition to the semiconductor industry, PHM can be applied in fault prognosis for equipment in the machinery, medicine, and power sectors, greatly reducing the uncertainty which machine malfunction brings.

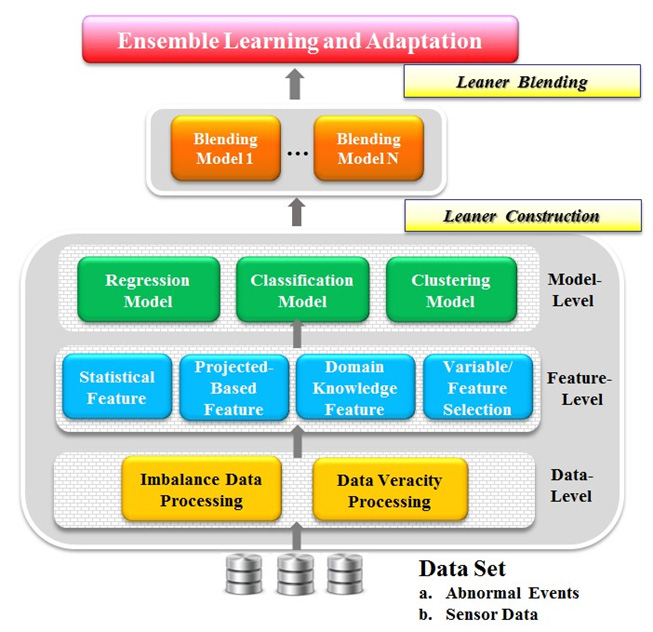

The chart below shows the operating flow of PHM, which can be divided into four levels: Data Level, Feature Level, Model Level, and Ensemble Learning and Adaptation Level. The Ensemble Learning model uses the concept of collective intelligence to fuse multiple machine learning algorithms to achieve a more robust prediction. Meanwhile, a TDD (time, diversity and discriminability) method is proposed to adaptively learn new ensemble weights based on incoming samples.

Four levels of PHM’s primary technology operating flow.

ITRI’s PHM is able to cut operation loss and maintenance labor cost by accurately predicting unexpected events, equipment failure, and component wear. It minimizes poor quality products and material wastes. For workers, the prediction of upcoming faults allows them to address issues earlier than they otherwise would, lessen the pressure and risks of inspection and repairing, and improve work quality and safety. For the environment, the use of PHM helps lengthen the lifespan of equipment and reduce scraps, making the manufacturing process more environment-friendly.