Activity

Unlocking the Potential of Smart Manufacturing at iMTduo 2018

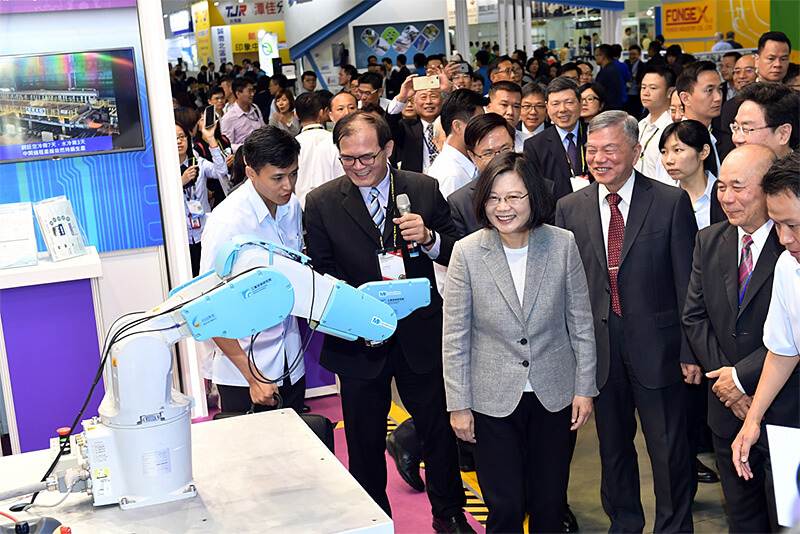

At the 2018 Taipei Intelligent Machinery & Manufacturing Technology Show (iMTduo), ITRI demonstrated smart manufacturing scenarios in transportation vehicle components and machine tool industries based on the architecture of smart manufacturing, such as IaaS, PaaS, and SaaS. Key technologies for smart manufacturing used in the PCB industry were also displayed to showcase the ways in which smart factories in the future can swiftly connect their production equipment.

Recently the strong demand from China and Europe for smart manufacturing has stimulated Taiwan’s machinery industries to advance their capabilities to grasp these market opportunities. Dr. Jwu-Sheng Hu, ITRI’s Vice President and General Director of Mechanical and Mechatronics Systems Research Laboratories, remarked that smart machinery, one of the highlights in the Government’s 5+2 Industrial Innovative Plan, can address the future trend of large variety and small volume production. Dr. Hu said that ITRI will continue to work with industrial partners to introduce advanced robotics, information, and artificial intelligence technologies into manufacturing processes.

At iMTduo 2018, ITRI exhibited the Smart Machine Box to show how it allows the visualization of production information and IoT connectivity, equipping manufacturers with a smart machinery environment in the IaaS level. The High Accuracy 3D Vision Inspection System combined with 3D and 2D image analysis and error detection also demonstrated its potential for satisfying the high-speed inspection demands required for high-end products in the aerospace industry.

Furthermore, ITRI’s spinoff Mechavision presented a highly sensitive and durable textile sensing technology for robots. When the surface of a robot bumps into things, the robot automatically stops at once. This new technology, which complies with ISO TS 15066, allows factories to take down safety grates surrounding the robots and actualize collaborative robotics without compromising the robots’ high efficiency.

In response to the issue that traditional small/medium-sized manufacturers have limited resources to develop IoT platforms, ITRI introduced the National IIoT PaaS (NIP). The platform service, displayed at the PaaS exhibition area, can link with domestically produced data gateways and help to store, process and analyze equipment procedure parameters or data collected from equipment sensors. By leveraging the high-performance computing platform, manufacturers can overcome big data access and computing restrictions. In addition, Cloud SCADA with OPC UA helps manufacturers unify the standards between equipment and machinery communication, reduce discrepancies between private communication standards, and establish Internet of Machines (IoM) monitoring platforms to better control the performance in production lines.

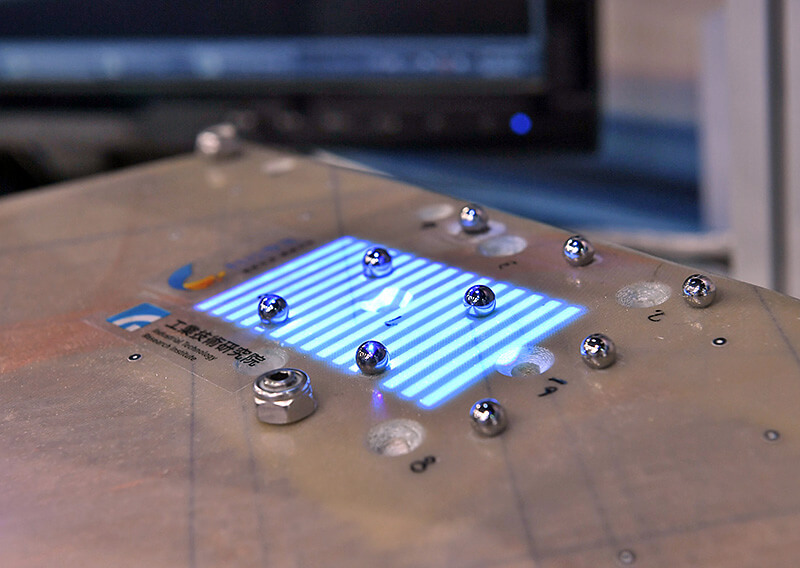

In the SaaS exhibition area, ITRI presented data applications that can be deployed after data is collected onto the platform via connected equipment, like the Platform of Warpage Control and the Auto AOI Classifier. By developing an array of different application module programs, ITRI aims to maximize efficiency in the production lines of high-output value industries such as PCB, machine tools, and transportation vehicle components.

At iMTduo 2018, ITRI also displayed various application scenarios for Cyber-Physical System (CPS) and remote control, for instance, a CPS manufacturing production line demonstration for the transportation vehicle components industry. Key technologies deployed at each production stage were demonstrated, including the Smart Machine Box, manufacturing process quality inspection and optimization, and equipment prognosis monitoring system (PMS). Another example was a smart factory production line demonstration for machine tools which features four core technologies: CNC monitoring system, Automatic Toolpath Generation Technology (iCAM), Production Scheduling System, and Intelligent Automatic Measurement System. A bike hub manufacturing scenario was presented to highlight the large variety and small volume production in a smart factory by remotely monitoring manufacturing sites located in Taichung and Nantou.