R&D Focus

Upgrading Plasma Processing for Display Production Garcia Liang and Jia-Jhih Shen

Driven by global markets of the metaverse, 5G, and smart vehicles, the demand for display products has been steadily growing. In panel manufacturing, plasma processing has been widely used, accounting for 50% of the display production equipment. Plasma processing equipment involving etching, coating, and surface modification are valued as important assets in the display industry as they can achieve high efficiency and yields. To improve the performance of the plasma processing equipment, ITRI recently developed two innovations.

With ITRI’s assistance, manufacturers now can independently build plasma systems and equipment.

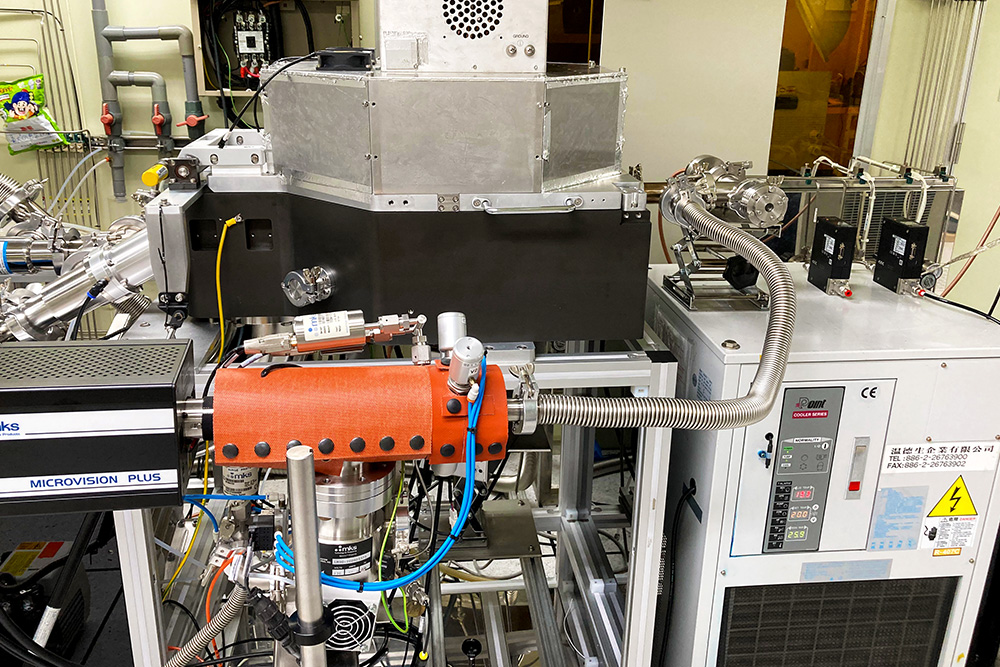

Plasma Source Design and Simulation Analysis

The new Plasma Source Design and Simulation Analysis uses a multi-physical coupling simulation software to conduct analyses based on the parameters of fluid dynamics, heat transfer, chemistry, and electric fields. This helps developers better design the key components of plasma equipment, such as the chamber.

With ITRI’s innovation, a new inductively coupled plasma (ICP) source equipment can generate plasma with high density over 1011 cm-3 and high uniformity above 95% (i.e., the non-uniformity is less than 5% on a 12-inch wafer). This technology has been applied to developing deposition and etching processes and proved to increase production capacity and yield, with reduced thin-film damages. The equipment can also perform low-temperature processes with low ion impacts.

Plasma Diagnosis and Monitoring Module

To optimize the density and uniformity of a plasma chamber, it is important to have not only simulation analysis but also accurate diagnosis of the equipment. ITRI’s Plasma Diagnosis and Monitoring Module is composed of three core technologies: (1) RF ion diagnostic measurement, (2) plasma spectral efficiency measurement, and (3) Langmuir probe measurement. With these technologies, the module can monitor the status of the plasma chamber to control the deposition and etching processes, issue abnormality alarms, and collect statistical data. This can effectively suppress plasma damage and film defects, ensure process stability, and increase productivity.

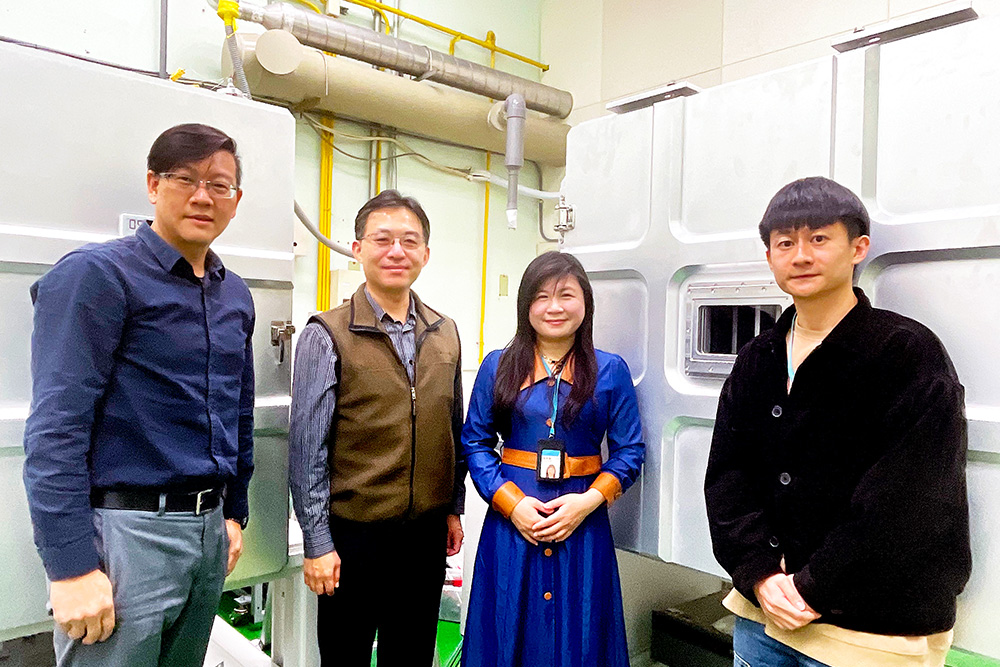

The research team of ITRI’s plasma processing development. From Left: Dr. Chih-Hung Liu, Dr. Bing-Shiang Yang, Garcia Liang, and Jia-Jhih Shen.

The multi-physics simulation for plasma equipment has been adopted by established plasma processing equipment makers in Taiwan and Japan. Besides guiding the manufacturers to independently develop next-generation plasma modules and intelligent dry-etching equipment, ITRI provided a total solution that integrates non-invasive plasma characteristics and processing diagnosis to meet the requirements of advanced nano-level processes.

“To deal with the challenge the future holds in plasma processing, I am glad to see ITRI working with a selection of industry players, and it does not stop there. With advancements such as simulation analysis and diagnosis monitoring of plasma sources, ITRI is bound to further its worldwide engagement and collaborations,” said ITRI’s Deputy General Director Dr. Bing-Shiang Yang.

“These techniques help industry players drastically reduce development time and stay competitive,” stressed ITRI’s Deputy Business Director Dr. Chih-Hung Liu. The efforts include assisting them to roll out diverse products spanning smart components, modules, systems, platforms, and equipment as well as carry out trials and verification tests with world-leading panel manufacturers.

ITRI has strengthened the core technology and complemented plasma process equipment with virtual predictions of the processing results. This empowers industry players to embrace the next-generation high-end plasma process equipment technology while enhancing their competitiveness and visibility in the global market.

About the Authors

Garcia Liang is a business manager of the Mechanical and Mechatronics Systems Research Laboratories at ITRI. She has dedicated herself to business promotion and international cooperation for ITRI.

Jia-Jhih Shen is a researcher of the Mechanical and Mechatronics Systems Research Laboratories at ITRI. He earned his B.S. and M.S. degrees in chemical engineering from Chung Yuan Christian University. His research focuses on plasma technology and application, with over 30 technical papers published.