Collaboration

ITRI Joins HARTU Project to Drive European Industries towards Collaborative Manufacturing

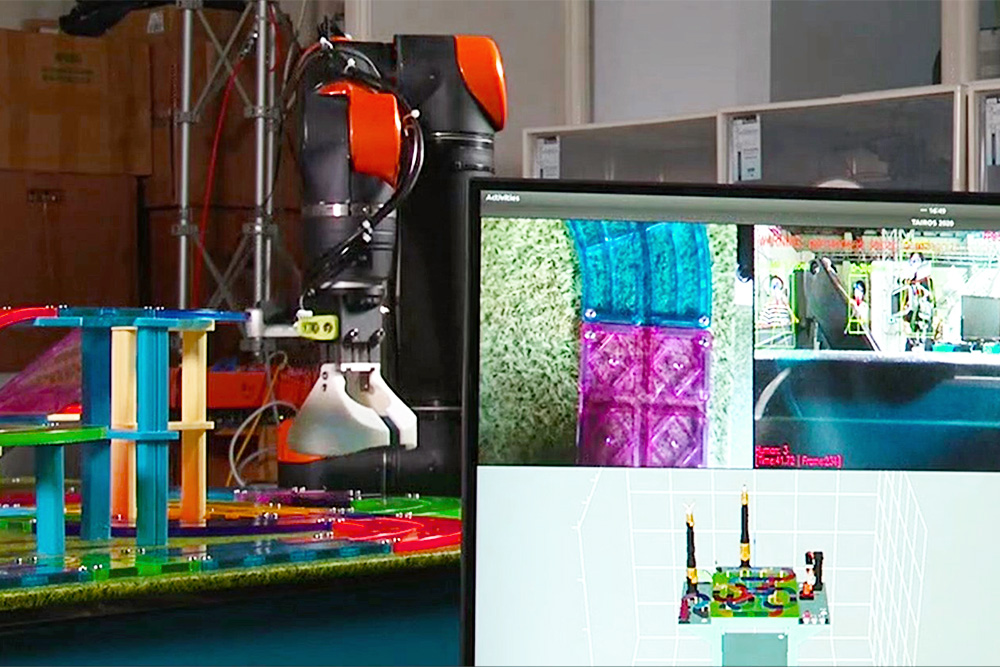

ITRI is actively engaged in Handling with AI-enhanced Robotic Technologies for flexible manufacturing (HARTU), an EU-funded project focusing on collaborative manufacturing. Combining the forces of 12 European and two Taiwanese companies and research institutions, the project aims to enhance production line efficiency and drive European industries towards collaborative 5.0 models using AI and robotics. Leveraging expertise in mechanical and mechatronic systems, ITRI is developing crucial technologies within HARTU, including grasp and release mechanisms for fixtureless grasp planners, and contact-rich assembly learning for fixtureless part handling.

“By integrating advanced robotics technologies into production lines, we can continuously enhance production efficiency,” said Dr. Shu Huang, Division Director of ITRI’s Mechanical and Mechatronics Systems Research Laboratories. “Within HARTU, ITRI is focusing on refining multi-robotic manipulation for contact-rich assembly tasks, with hand-tool assembly being one of the key use cases. Our goal is to introduce AI-enabled robotic technologies into assembly systems to present an innovative manufacturing platform and validate HARTU-developed components,” said Huang.

ITRI is focusing on multi-robot collaboration technologies to enhance robots’ abilities in manipulating and assembling objects of diverse sizes, shapes, and materials.

HARTU project coordinator Iñaki Maurtua highlighted the trend towards mass customization and the project’s role in addressing it. “The growing demand for a wide range of products in smaller quantities, coupled with e-commerce services, has driven the need for more flexible manipulation tasks,” noted Maurtua. “HARTU addresses this necessity by introducing innovative gripper concepts and AI learning techniques, enabling production lines to adapt to parts that vary in size, shape, and characteristics,” he stated.

HARTU is a three-year project that commenced in 2023. Funded by the EU’s key funding program Horizon Europe, HARTU researchers are targeting specific manufacturing scenarios to optimize flexibility and production line efficiency using innovative robotic components. Participants in the project include Tekniker, the German Research Centre for Artificial Intelligence GmbH (DFKI), Philips Consumer Lifestyle, Taiwan’s hand tool manufacturer Infar Industrial, and many more.