Feature

Manufacturing Tech with Sustainability at the Core

In the recent announcement of the 2023 R&D 100 Awards, five of ITRI’s accolades go to its sustainable manufacturing solutions, reflecting the Institute’s alignment with the global net-zero trend. These innovations include the VOC-3R System, HEAD-Matrix ALD+ System, O-RAN Energy-Efficient Private Network Management Technology, AI-Driven Optimization for Precision Manufacturing, and SENSE.

“Manufacturing stands at the forefront of carbon emissions, significantly impacting our environment. In light of the increasing demand for sustainable products, it becomes imperative to prioritize eco-friendly production methods. ITRI’s five award-winning innovations not only advance various manufacturing aspects but also are designed to streamline production processes and markedly enhance energy efficiency,” remarked ITRI President Edwin Liu.

VOC-3R System

The VOC-3R System, co-developed with Taimide, a leading polyimide film manufacturer, is an innovative solution for volatile organic compound (VOC) recovery in manufacturing processes using organic solvents. Suitable for various industries like electronics, pharmaceuticals, and coatings, the system addresses environmental concerns by capturing solvents from exhaust gases, eliminating direct carbon emissions. While traditional methods generated significant carbon emissions, this system ensures zero direct carbon emissions.

The three Rs of the VOC-3R System stand for CO2 reduction, solvent reclaim, and waste resourcezation.

Taimide, which produces 1,500 metric tons annually, faced challenges due to significant VOC emissions during its production processes. The baking phase released substantial VOCs, and conventional treatment methods were inefficient, resulting in secondary waste issues. Every kilogram of PI film produced led to approximately 5 to 6 kilograms of VOCs. The VOC-3R System successfully addresses this issue, effectively recovering solvents from exhaust gases. This adoption resulted in a noteworthy annual reduction of approximately 20,000 metric tons of direct carbon emissions, marking a significant stride in curtailing CO2 emissions in the polyimide film industry.

Notably, this technology provides an economically feasible and environmentally sustainable alternative, aligning with the global push for net-zero goals. Moreover, it promotes an environmental, social, and governance (ESG) framework in manufacturing, exemplifying a pivotal step toward greener industrial practices.

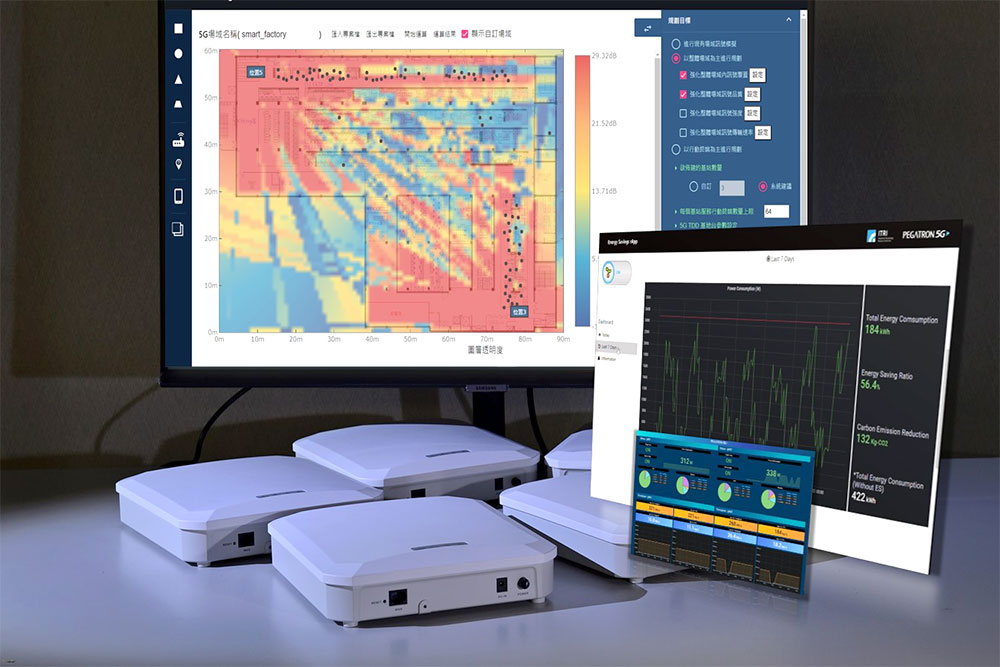

O-RAN Energy-efficient Private Network Management Technology

O-RAN Energy-efficient Private Network Management Technology is the world’s first 5G open radio access network (O-RAN) private network management system with energy savings. It was co-developed with leading electronics manufacturer PEGATRON Corporation , which includes this system in its 5G O-RAN products. This technology contributes to reducing energy consumption and can be used with any private network, field, or base station brand.

The energy-saving management platform for 5G-ORAN private networks is adaptable to any private networks, fields, and brands of base stations.

-

High deployment efficiency: A single click mimics base stations to plan a private network. It provides base stations plug-and-play and performs automatic optimization, monitoring, and repair capabilities to reduce operation and maintenance costs.

-

Energy savings: Artificial intelligence (AI) monitors flows and diversions for smart distribution and allows idle base stations to hibernate for energy savings. According to real-world trial results, this method saves 20% on power consumption.

-

Smart modularization: It allows for agile private network deployment in 5G vertical applications such as hospitals, entertainment, warehouses, logistics, and drones.

According to IEEE research, base stations consume 50% to 60% of private network electricity. This system decreases energy usage through flow monitoring and diversion, allowing idle base stations to sleep. Its one-click deployment function reduces deployment time by 80% because its AI optimizes, monitors, and repairs base stations in minutes. Furthermore, clever modularization offers a tailored developer interface for individual network requirements and adaptable applications.

HEAD-Matrix ALD+ System

The HEAD-Matrix ALD+ System streamlines semiconductor manufacturing by integrating multiple deposition processes into a single chamber, enhancing accuracy, efficiency, and sustainability. It meets the demands of high aspect ratios, multicomponent uniformity, and precise application of thin films.

HEAD-Matrix ALD+ satisfies the semiconductor process requirements of a high aspect ratio, multicomponent uniformity, and precise application of dense thin films.

It can be applied to emerging industries such as the semiconductor industry, OLED optoelectronic components, LED lighting, LCD backlight panels, solar photovoltaics, thin-film solid-state batteries, biomedical chip sensors, and 5G wireless communications devices.

HEAD-Matrix ALD+ has been tested and verified by upstream and downstream leading manufacturers, including leading domestic and foreign equipment and device manufacturers.

-

High aspect ratio: It meets the memory 3D IC high aspect ratio requirement.

-

High uniformity: As the size of chip components decreases during the 3D IC process, HEAD-Matrix ALD+ addresses the problem of conformal deposition of thin films containing multiple components that are uniform in thickness.

-

Enhance devices’ lifetime and production yield: It ensures a high rate of product yield. The prototype system will undergo production validation to meet commercial product specifications.

-

Energy savings and carbon reduction: It significantly reduces equipment footprint and cost, and effectively abbreviates the transmission time of wafer replacement in the deposition process to increase production capacity and achieve energy savings and carbon reduction as a result.

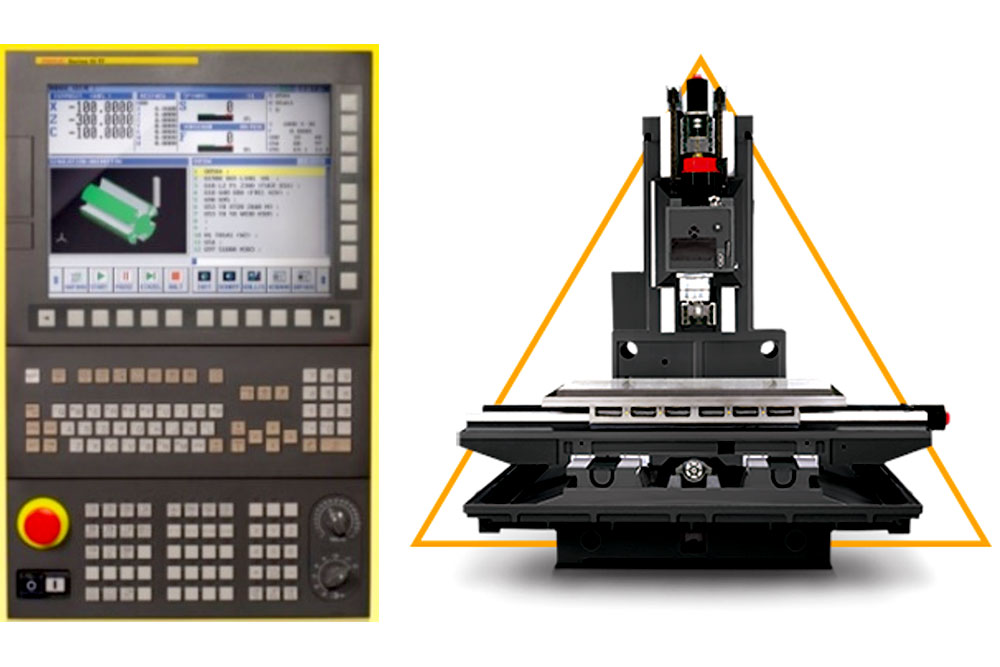

AI-Driven Optimization for Precision Manufacturing

The AI-Driven Optimization for Precision Manufacturing software significantly improves the accuracy of machine tools for high-precision manufacturing, reducing production errors, time, and costs. It enables high-precision and customized machining processes without the need for precise temperature control from the process environment (e.g., 25±4°C). Unlike manual adjustment, which takes at least 14 days, this software can be rapidly adjusted and calibrated within just 30 minutes.

High-precision machining is a manufacturing process using advanced tools, machinery, and control techniques to achieve highly accurate and precise machining of workpieces at the micron or even submicron scale. Common applications for high-precision machining include the automotive industry, semiconductor fabrication, precision instruments, and optical components.

The AI-Driven Optimization for Precision Manufacturing software can adjust and calibrate high-precision machining equipment within just 30 minutes.

To reach micron-scale machining accuracy is quite challenging; many factors, such as stability, accuracy, processed materials, and the operating capabilities of the machine tools have direct impacts on product quality. Before the introduction of this technology, a manufacturer could only count on skilled and experienced technicians to try and minimize errors, but errors still occurred, which increased the costs and time to meet the requirements.

This innovation has three features:

-

A built-in machining feature recognition function, advanced sensor monitoring technology, image recognition and analysis technology, and an AI control parameter optimization learning module to optimize the process.

-

The software enables high-precision, accurate, and customized machining processes without the need for precise temperature control from the process environment (e.g., 25±4°C). Unlike manual adjustment, which takes at least 14 days, this software can be rapidly adjusted and calibrated within just 30 minutes.

-

It achieves high-precision machining even with equipment that lacks professional calibration capabilities.

SENSE

Smart Energy for a Sustainable Ecosystem (SENSE) is a collection of environmentally friendly recycling power solutions. It includes mobile electricity consumption (for example, electric vehicles), turnover electricity consumption (e.g. an electric energy supplementary system), and dispatching electricity consumption (e.g. an energy storage system and a power grid). It can triple the service life of various electric energy units, from batteries to energy storage, minimize energy loss by 35%, and reduce construction costs by 30%. SENSE is a successful example of employing recycled resources to create batteries, and performing long-term battery management, which is completely consistent with the sustainable development trend.

SENSE was developed in partnership with CPC Corporation, Taiwan, a state-owned enterprise established in 1976 and one of the largest petroleum companies in Taiwan. This technology is conducive to CPC’s transformation from a primary focus on petroleum to actively investing in green energy projects, providing a more environmentally friendly energy supply for electric vehicles to respond to future market changes.

SENSE pioneers in aggregating diverse power sources, including waste EV batteries, optimizing distribution dispatch and cutting carbon emissions.