Feature

Paving the Way for Sustainable Garment Recycling

By efficiently removing dyes from discarded polyester fabrics, PureTex mitigates environmental hazards associated with new clothing production.

The fashion industry faces a mounting challenge: fulfilling pledges to incorporate recycled materials while minimizing environmental impact. Leading brands like Adidas, Nike, and Lululemon aim to include at least 30% recycled polyester in their products by 2030. However, recycled plastic bottles offer a finite source, and challenges such as decolorization inefficiency and the high costs associated with pollutant treatment further hinder progress. This results in a mere 0.001% of discarded textiles being recycled back into garments.

ITRI’s innovative PureTex Sustainable Decolorization Solution tackles this head-on. This water-based technology effectively removes dyes from used polyester fabrics, restoring them to their original color in an eco-friendly and energy-saving way.

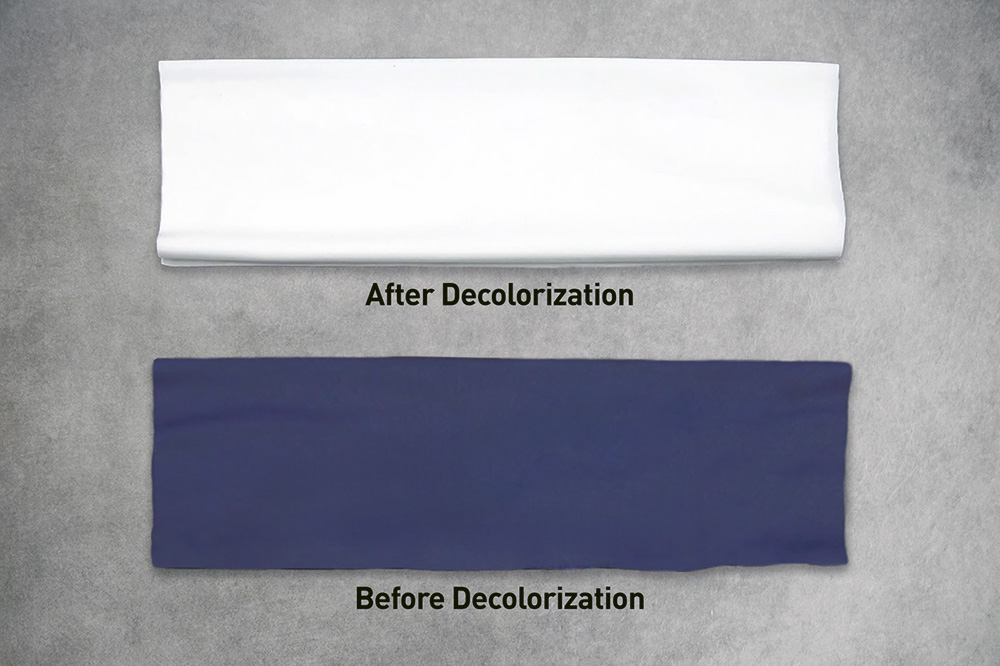

PureTex effectively restores recycled textiles to their original colors, paving the way for closed-loop textile recycling.

Traditional decolorization relies heavily on organic solvents and high operating temperatures ranging from 120°C to 210°C. These methods not only pollute the air with volatile organic compounds (VOCs) but also achieve only a 70% dye removal rate, limiting the usability of recycled fibers to dark-color fabrics or non-textile applications. PureTex overcomes these challenges with a removal efficiency exceeding 95% while operating at just 90°C, significantly surpassing previous technological limitations. By opening fiber molecular chains in a non-crystalline state, it allows for the easy removal of dye molecules across the full color gamut.

Moreover, PureTex boasts impressive environmental benefits. Its low operating temperature reduces carbon emissions by approximately 55.6%, and its solvent-free composition ensures zero VOC emissions, making it a truly eco-friendly decolorization solution.

In just 2-4 hours, textiles treated with PureTex undergo deep decolorization, producing high-quality polyester raw materials in their original color and ultimately increasing the reusability of recycled fibers. What’s more, PureTex is conducive to large-scale deployment, as it doesn’t require facility updates to be integrated into existing dyeing processes, enabling manufacturers to scale production sustainably without additional costs.

The before (lower) and after (upper) decolorization effects of PureTex on textiles.

Dr. Chang-Jung Chang, Division Director of ITRI’s Material and Chemical Research Laboratories, emphasizes the transformative potential of PureTex: “As Taiwan’s textile industry is a global leader in functional textiles, supplying 80% of the world’s materials, the circulation and sustainability of textile materials are of paramount importance globally. Upon the commercial application of this technology, discarded textile materials and production scraps can enter the textile recycling chain, advancing us towards a closed-loop cycle.”

PureTex not only facilitates garment-to-garment closed-loop circularity but also aligns with the ambitious 100% worldwide material recycling goal set by over 200 leading fashion brands for 2030. By efficiently removing dyes from discarded polyester fabrics, PureTex mitigates environmental hazards associated with new clothing production, marking a significant step towards a more sustainable future for the fashion industry.