R&D Focus

Unlocking the Potential of Pineapple Leaves From Farm Waste to Textile Fibers

The intersection of technology and nature is driving breakthroughs in sustainable fashion. Pineapples, once just a tropical fruit found on the table, are now becoming an important input to the clothes you wear. This innovation is made possible by ITRI’s plant fabric extraction system, an all-in-one process solution that efficiently treats pineapple leaf waste, transforming it into eco-friendly materials the textile industry can use to replace cotton, linen, polyester, or leather.

Pineapple leaves feature high cellulose content and can provide competitive and high-quality fibers for textiles.

Where did the idea come from?

Taiwan, known as the Kingdom of Fruits, produces about 480,000 tons of pineapples each year, yet generates 700,000 tons of leaf waste. Therefore, resolving the disposal issue has become an intriguing subject to ITRI researchers. “At ITRI, we have extensive experience in transforming agricultural residuals to high-value, sustainable products. For example, we have converted lemon scraps into cow feed additives and cellulose into butanol. Recently we have identified great potential in pineapple leaves,” said Shih-Chi Lee, Deputy General Director of ITRI Central Region Campus. “The tough pineapple leaves, rich in durable, tensile natural fibers, can be processed into textile materials and serve as an eco-friendly alternative to polyester, reducing the environmental footprint in textile manufacturing,” he shared.

ITRI’s Role

So how exactly did ITRI help pineapple farmers process the massive amount of leaf waste and extract the fibers that can be used by textile manufacturers?

The research team worked with Pinacell Co. Ltd. and its organic pineapple farm to address this issue. They found that current extraction practices including manual processes and roller-type machines lack quality assurance. Without adequate cleaning, the residual mucus in the fiber makes the subsequent treatment process cumbersome and unable to provide a stable supply for textile manufacturers.

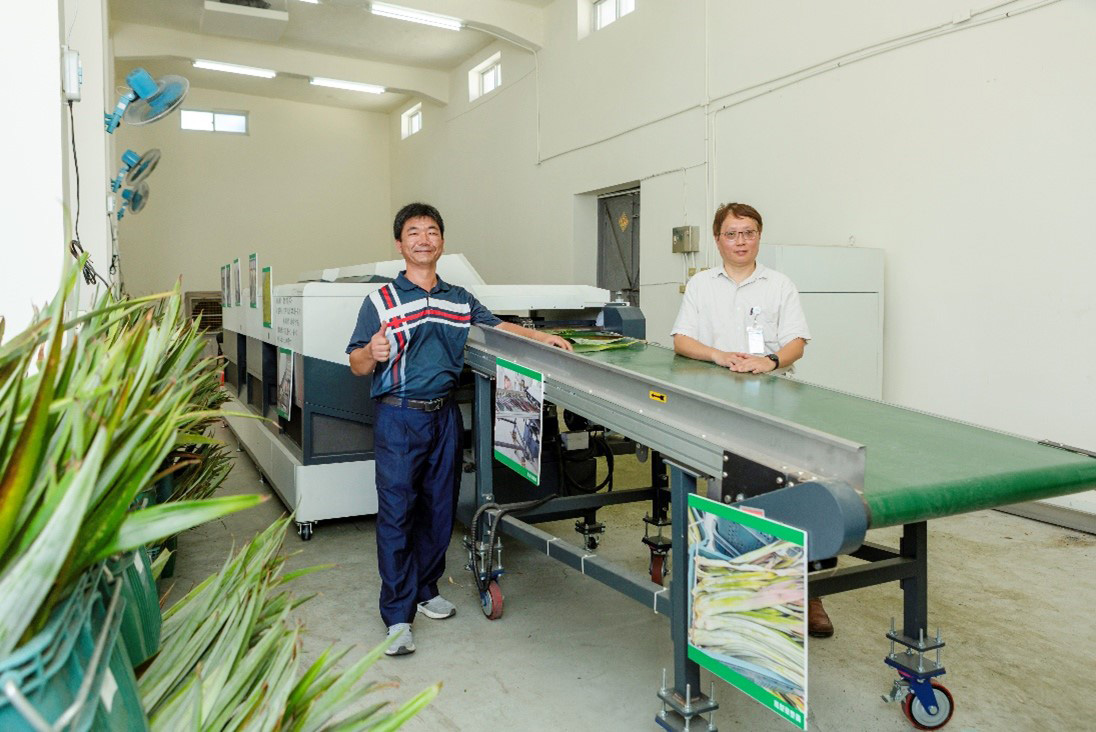

ITRI’s plant fabric extraction system provides an all-in-one process solution for pineapple leaf waste treatment.

Focusing on the pain points, ITRI developed a plant fabric extraction system to fill this gap. This fully automated mechanical solution takes advantage of Taiwan’s manufacturing strengths in processing machinery. It automates and integrates the processes of cutting, extraction, and cleaning. According to Chao Chun Lo, Engineer at ITRI Central Region Campus, unlike traditional manual or semi-automated scraping processes, this system offers significant improvements, completing the three treatment stages (scraping-washing-scraping) within 30 seconds. This accelerates the pineapple leaf fiber extraction process by over 50%, and achieves a fiber cleanliness level exceeding 80%. J.M. Ba, CEO of Pinacell, also acknowledged the collaboration with ITRI, commending that the process efficiently treats waste organic pineapple leaves and secures a stable supply for its partner textile company.

Benefits and Future Applications

Lee pointed out that compared to chemical defibrillation used to extract biomass fibers, ITRI’s technology incorporates a mechanical approach into a treatment system for local material processing. Regardless of the shape or size of pineapple stems and leaves, the newly-developed equipment can perform dry or wet scraping, pull out fibers, and complete the cleaning process. This automated process guarantees the consistency of product quality and supports zero waste and sustainability goals.

ITRI’s innovation offers a waste disposal and utilization solution alternative to composting pineapple leaves, which is often time-consuming and costly. The system is easy to operate, cost-effective, and provides solid help to budget-limited farmers. Besides pineapple leaves, it can also be applied to banana pseudo-stem processing. The successful collaboration between ITRI, farmers, and the textile industry also exemplifies the creation of a sustainable ecosystem that contributes to a circular economy.