R&D Focus

Technology Highlights at Touch Taiwan 2025

At Touch Taiwan 2025, ITRI joined hands with key industry partners to exhibit its latest technological innovations, showcasing novel solutions for panel-level packaging, advanced display manufacturing, and smart display applications. Featured technologies include the Total Solution for High Aspect Ratio Panel-Level Packaging, Quantum Dot Color Conversion (QDCC) Film Technology, Continuous Depth-of-Field 3D AR-HUD, 5G Transparent Antenna Communication LCD Window, and NextGen Sensor-Integrated Eye-Tracking System.

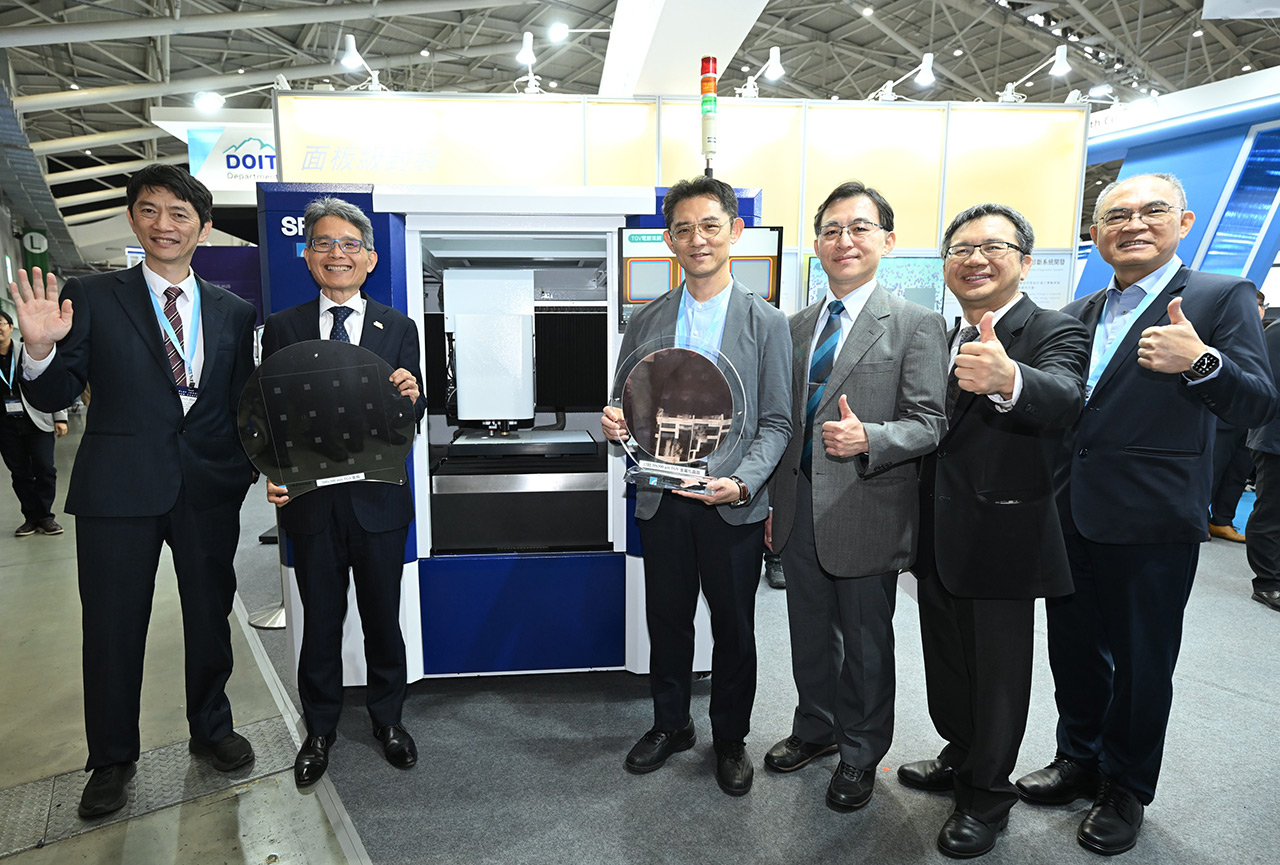

Total Solution for High Aspect Ratio Panel-Level Packaging

In response to the growing demand for advanced chiplet and AI chip packaging, ITRI has developed the world’s first total solution for high aspect ratio panel-level packaging. This breakthrough increases the aspect ratio of vias from 10 to 15 on 12-inch wafers and boosts interconnect density by over 50%, overcoming the current limitations of through-glass via (TGV) fabrication.

ITRI’s total solution for high aspect ratio panel-level packaging boosts interconnect density, drilling speed, and production yield.

Incorporating high-speed laser modification and etching processes, ITRI’s solution elevates the drilling speed tenfold and achieves a high yield of over 99%. Moreover, its all-wet deposition process cuts costs in half compared to traditional dry coating methods. ITRI has collaborated with local material and equipment suppliers to create a comprehensive solution for drilling, filling, grinding, and testing in panel-level packaging. This advancement is poised to support high-speed, high-frequency communication and computing applications, propelling innovation in semiconductor packaging technology.

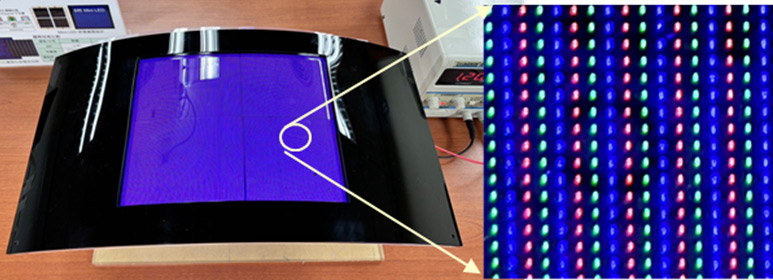

Quantum Dot Color Conversion Film Technology

Full-color Micro LED displays are emerging as a leading next-generation display solution. However, the manufacturing process still faces challenges in RGB chip mass transfer and repair. ITRI’s QDCC Film Technology uses a single blue LED to generate green or red light, improving chip transfer efficiency and output quality.

Using the sol-gel method, ITRI researchers synthesized siloxane resin nano-scattering particles and combined them with QDs featuring SQS-POSS ligands for high dispersion and stability. The solvent-free QDCC ink offers excellent sprayability, making it ideal for inkjet printing (IJP). Full-color IJP enables the fabrication of an island-type QDCC array with high-resolution patterning. The QDCC film reaches 18 µm thickness, ensuring durability and strong optical properties. Moreover, its material utilization rate is twice that of traditional methods, which typically achieve less than 30%. The technology also reduces the need for two photomasks, further shortening development time, lowering R&D costs, and reducing carbon emissions.

Quantum Dot Color Conversion Film Technology removes barriers to efficient chip mass transfer and repair in Micro LED display assembly.

Continuous Depth-of-Field 3D AR-HUD

The Continuous Depth-of-Field 3D AR-HUD addresses the pain points of existing AR-HUDs, which can cause dizziness with 3D visuals and often suffer from misaligned virtual cues. The technology integrates a light field display unit with a freeform AR-HUD optical design and efficient eye-tracking capabilities, improving depth perception and minimizing driver distraction in AR automotive displays.

The Continuous Depth-of-Field 3D AR-HUD can project images that appear anywhere from 3 to 15 meters in front of the driver.

Leveraging advanced light field technology, stereoscopic images and navigation information are projected onto the vehicle’s windshield with spatial depth, spanning a range of 3 to 15 meters within the driver’s field of view. This natural display method eliminates spatial parallax between the projected imagery and real-world background objects, enhancing driving safety and the efficiency of information transmission.

The system employs a world-leading automotive transparent projection film, offering superior clarity and optical performance. Its optical loss rate is only one-fifth that of competing products, and its haze rate is just 3.5%—much lower than the approximately 14% found in existing solutions. Moreover, the eye-tracking system provides greater precision than face orientation detection methods. It detects the driver’s gaze in real time with a tracking error of ≤5°, dynamically adjusting the projected content based on the gaze position.

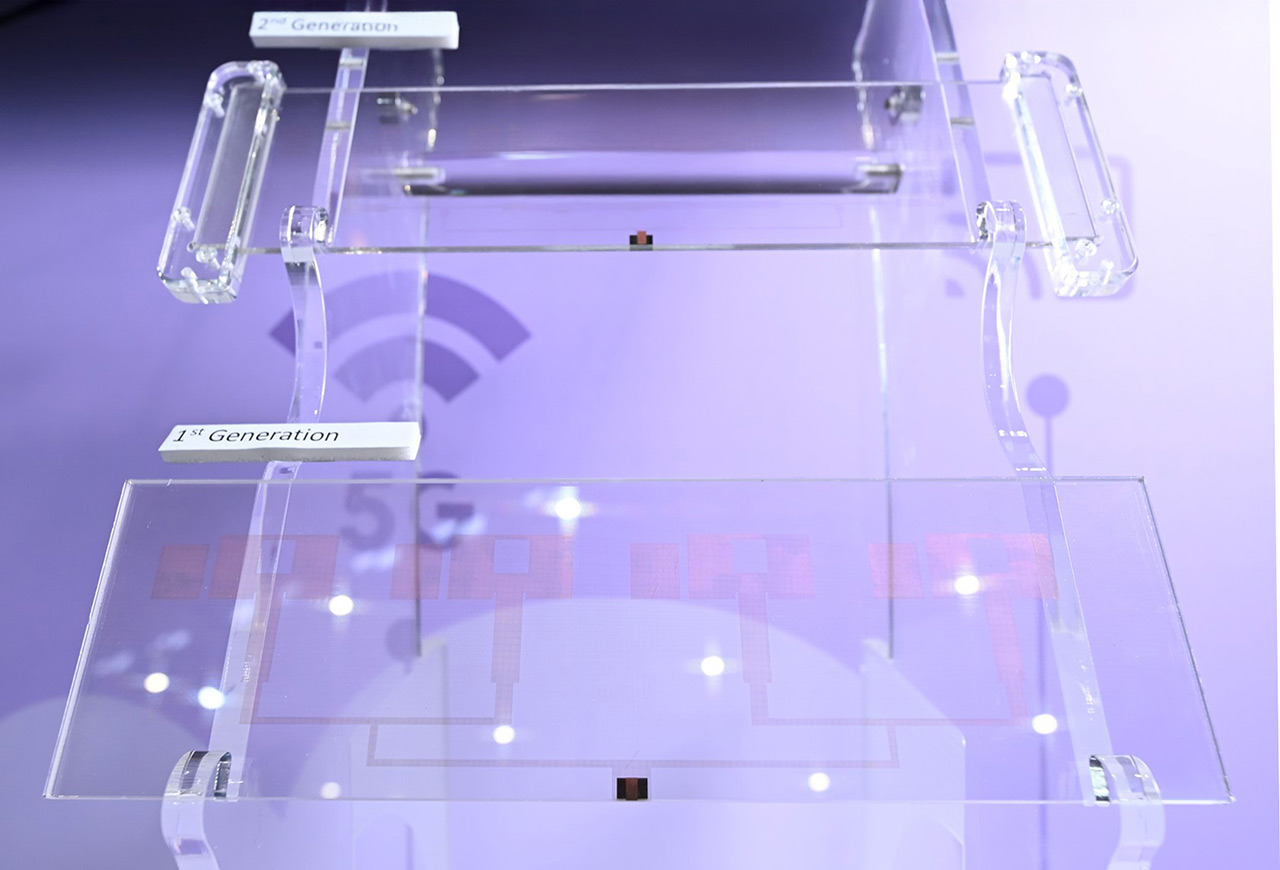

5G Transparent Antenna Communication LCD Window

ITRI has developed a 5G transparent array antenna module to deliver integrated wireless communication technology solutions for smart living. This module is integrated with Innolux’s LCD smart windows as a curtain replacement with dimming and energy-saving features while also serving as a base station for 5G signal reception. Through copper mesh technology, the antenna achieves over 80% optical transparency and reliable RF performance, with a peak gain of 12 dBi.

A 5G transparent array antenna module is integrated into an LCD smart window to enable wireless communications.

The system converts 5G n78 signals into Wi-Fi via backend customer premises equipment (CPE), boosting signal performance and wireless connectivity to improve indoor network coverage. The power consumption of the module is as low as 0.1 W/m².

ITRI has also partnered with Compal Electronics to co-develop a laptop equipped with a transparent Wi-Fi antenna, providing versatile flexibility in adapting to different product designs. These collaborations accelerate the integration of IoT technologies into smart home applications.

NextGen Sensor-Integrated Eye-Tracking System

Most AR/VR glasses on the market rely on hand gestures or external controllers for operation. To make hands-free control possible, ITRI has developed advanced optical eye-tracking technology within smart glasses. By embedding micro-sensing components in the lenses, the sensors are able to capture eye movements in real time and allow users to navigate and control the mouse pointer using only their eyes.

The NextGen Sensor-Integrated Eye-Tracking System features a compact design.

Unlike bulky assemblies made from discrete components, this solution utilizes a highly integrated module that packages eye-tracking sensors, infrared emitters, and image processing circuits into a single compact unit, resulting in a more streamlined and lightweight design. Compared to conventional camera-based eye-tracking systems, this technology reduces power consumption by 90% and triples processing speed.

The NextGen Sensor-Integrated Eye-Tracking System creates more intuitive human-computer interactions and immersive 3D experiences in XR environments through precise eye-tracking. Secured by multiple international patents, this innovative technology is expected to accelerate development in outdoor use, smart manufacturing monitoring, and entertainment.