Collaboration

ITRI and Mitsubishi Electric Launch CO2 Capture Demonstration Projects

ITRI and Mitsubishi Electric Corporation have collaborated to launch demonstration projects in both Japan and Taiwan, showcasing the real-world applications of ITRI’s CO2 capture technology. The shared mission is expected to accelerate the deployment of CO2 capture and utilization (CCU) systems and to achieve carbon neutrality.

Japan: Testing ITRI’s Solid Amine Sorbent CO2 Capture Technology

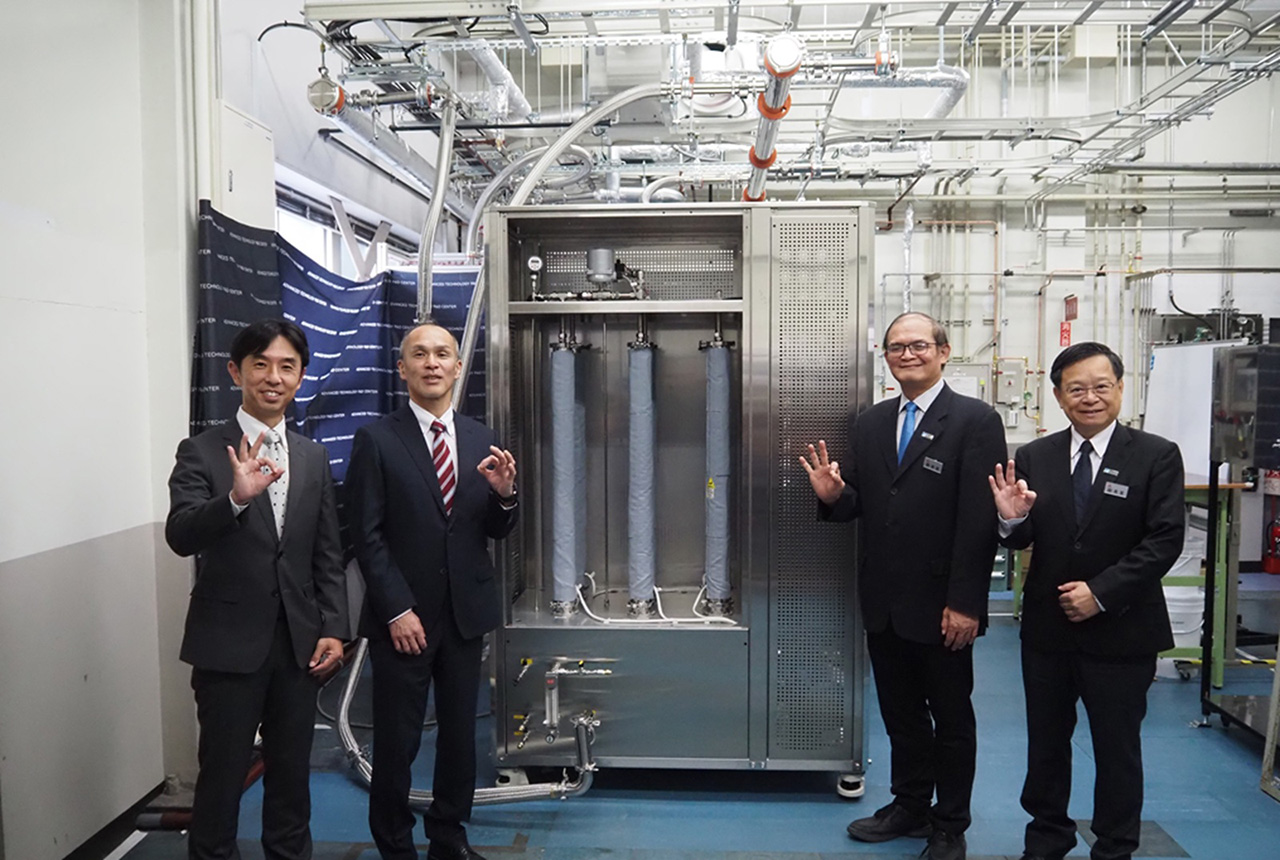

In June 2025, Mitsubishi Electric began demonstration testing of a CO2 capture facility developed by ITRI and installed at its Advanced Technology R&D Center in Amagasaki, Hyogo Prefecture, Japan. This trial focuses on utilizing a solid adsorption method to capture CO2 from the flue gas of a steam-generating boiler and will continue until September 2027.

ITRI’s CO2 capture technology is being demonstrated and tested at Mitsubishi Electric’s R&D center in Hyogo, Japan.

According to Hou-Peng Wan, Deputy General Director of ITRI’s Green Energy and Environment Research Laboratories, the ITRI-developed solid amine adsorption technology “acts like a breathing sponge.” It captures CO2 from dilute gas streams and releases it for recovery by heating to around 80°C. Unlike traditional liquid absorption methods, it consumes less energy by eliminating the need for evaporating aqueous solutions, making it especially suitable for small, distributed emission sources like natural gas boilers, fuel cells, and semiconductor facilities. In addition to its low-temperature desorption and energy-saving advantages, the technology also features compact equipment size, long lifespan, and excellent thermal stability, strengthening its potential to scale up for broader industrial adoption.

Mitsubishi Electric has integrated the facility into a comprehensive CCU system and is leveraging its expertise in system design, control, and energy management to enhance energy efficiency and operational effectiveness. By building on the results of this demonstration, ITRI and Mitsubishi Electric aim to bring integrated CCU technology into active use in industrial settings, contributing to emissions reduction and sustainable manufacturing.

Taiwan: Capturing and Reusing CO2 in Beer Production

As a next step in expanding CCU applications, ITRI, Mitsubishi Electric, and Taiwan Tobacco & Liquor Corporation (TTL) signed a collaboration agreement in August 2025 to initiate a demonstration project at TTL’s Jhunan Brewery in Taiwan. The project aims to capture CO2 emitted during the beer production process and purify it for reuse within the same facility, creating a closed-loop carbon recycling system.

ITRI, Mitsubishi Electric, and TTL signed a tripartite collaboration agreement to develop a CCU pilot plant at a brewery.

In this collaboration, ITRI provides the solid amine carbon capture technology, Mitsubishi Electric leads process control optimization, and TTL’s Jhunan Brewery supplies flue gas and the test site. Together, the trial will validate a high-efficiency carbon capture system and explore resource reuse in brewing processes, demonstrating a scalable, circular carbon management practice. Pilot operation is scheduled to begin in 2026.

ITRI Executive Vice President Jwu-Sheng Hu emphasized the significance of this tripartite cooperation. “Carbon should be seen not as a burden, but as a recyclable asset. This Taiwan-Japan collaboration is a key milestone in advancing research, localization, and commercialization of CCU systems in diverse industrial environments,” he said.

Shaping a Sustainable Future

ITRI is committed to developing cutting-edge, adaptable technologies that meet industry needs and promote global carbon reduction goals. Since signing the initial collaboration agreement with Mitsubishi Electric in April 2024, ITRI has shared valuable R&D expertise in CO2 capture, along with practical experience in industrial applications and system integration.

As both demonstration sites continue to generate data and insights, ITRI and its partners will refine and optimize CCU systems, targeting early commercial deployment. These efforts support decarbonization strategies and offer a replicable model for international industries seeking sustainable carbon management solutions.