Activity

Industrial Robots for Advanced Manufacturing

During the 2019 Taiwan Automation Intelligence and Robot Show (TAIROS), ITRI displayed smart machinery innovations that are the result of the government’s 5+2 Industrial Innovation Plan. These tech advancements show how ITRI has introduced new production models to vendors, allowing them to respond to low-volume, high-mix requirements and improving their production efficiency and quality to satisfy customized needs.

Dr. Jwu-Sheng Hu, ITRI’s Vice President and General Director of Mechanical and Mechatronics Systems Research Laboratories, stated that ITRI is developing innovative high-end, cross-field robotic technologies such as the integrated multifunctional robot and inspection system, and moreover, investing in the development of robot networking standards. All these efforts are made to support the industry, enabling more automated and flexible manufacturing procedures. The goal is to break through the bottleneck in smart manufacturing upgrades so that companies can rapidly enter the international market, he said.

ITRI’s tech highlights displayed at TAIROS 2019 include:

Intelligent Grinding Machine and Surface Defect Detection System

ITRI’s intelligent grinding machine has two sanding belts with different grits. Integrated with a surface defect detection system, this belt grinder can conduct both coarse and fine grinding and polishing, as well as detect defects. In addition, it has a multiple contact wheel design and a rotating platform that can change the shape of the sand belt and adjust the angle and width to match various workpieces. The belt sander can also be rotated to match the grinding with the robotic arm and reduce missed areas. On the other hand, the surface defect detection system has AI image inspection that can help to determine whether a workpiece is defective, which reduces manual inspection time. The three-in-one machine design does not take up space, meaning that users can better utilize factory space. This innovation has been used in the plumbing hardware industry. This year it was also adopted by Solas, a jet ski propeller company with over 90% of the industry market share, to grind its propeller blades, analyze its product quality, and increase its production yield.

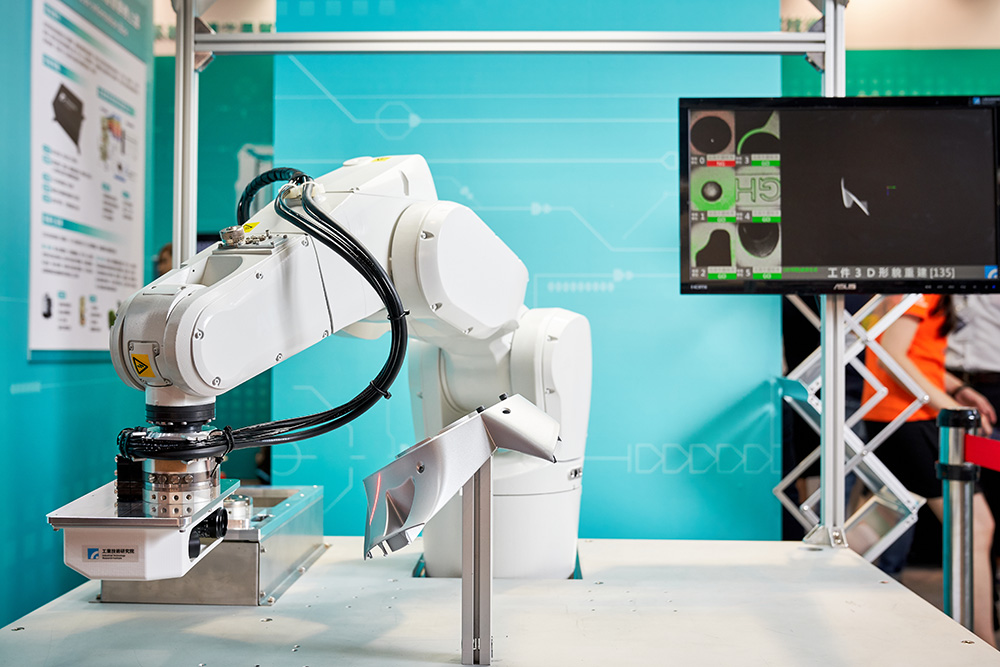

Online 3D Vision Inspection System

To perform defect inspection of workpieces with larger size, the inspection camera needs to be dynamically positioned. ITRI debuted its online 3D vision inspection system with a robot arm. This system can simultaneously implement 2D and 3D vision inspection on large-sized curved workpieces, meeting diverse inspection requirements within one station. Currently, ITRI is cooperating with Aerospace Industrial Development Corporation to develop a process measurement system that can visually inspect highly curved and large workpieces. Other applications include vehicle parts, mold injection, and stamping products.

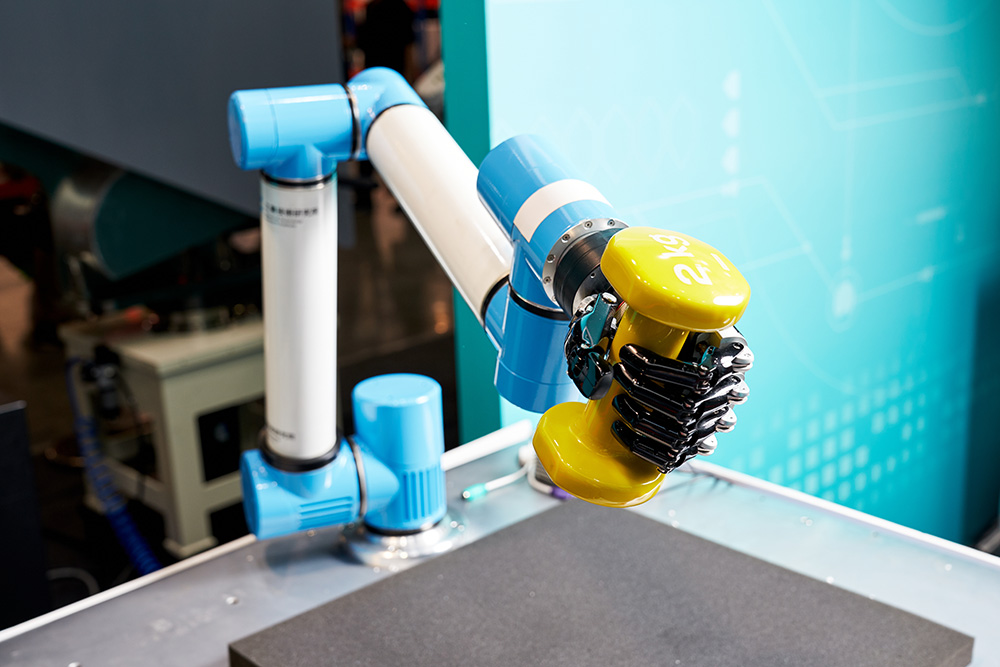

Human-like Robotic Hand

Unlike ordinary prostheses which can only move the entire palm or just one or two fingers, the human-like robotic hand developed by ITRI can move all five fingers. The robotic control and spring design allows the fingers to respond when the prosthetic hand hits a hard object. This anthropomorphic hand can help physically disabled people conduct daily functions, such as holding a plastic bottle. In addition, it can be used to grab irregularly shaped and soft objects—a great improvement from the conventional clamp. This technology is also suitable for feeding or discharging material in factories, loading and offloading products in stores, and for inspecting livestock farms.

Robotic Arm with Smart Joints

Traditional bulky robots, with fixed arm length and structure, are unable to meet increasingly complex production specifications. ITRI’s robotic arm with smart joints is precise, lightweight, and compact. Not only are the motors, sensors, and power converters integrated, but the robotic arm can be assembled with multi-axis joints like building blocks according to specific needs. The robotic arm weighs a total of approximately 12 kg and can bear a load of 6 kg. Moreover, it has a ±0.02 m repeatable precision and can be applied to industrial manufacturing, robot training, DIY applications, and academic research.