Collaboration

Bogie Running Tester Enhances High Speed Train Testing Efficiency

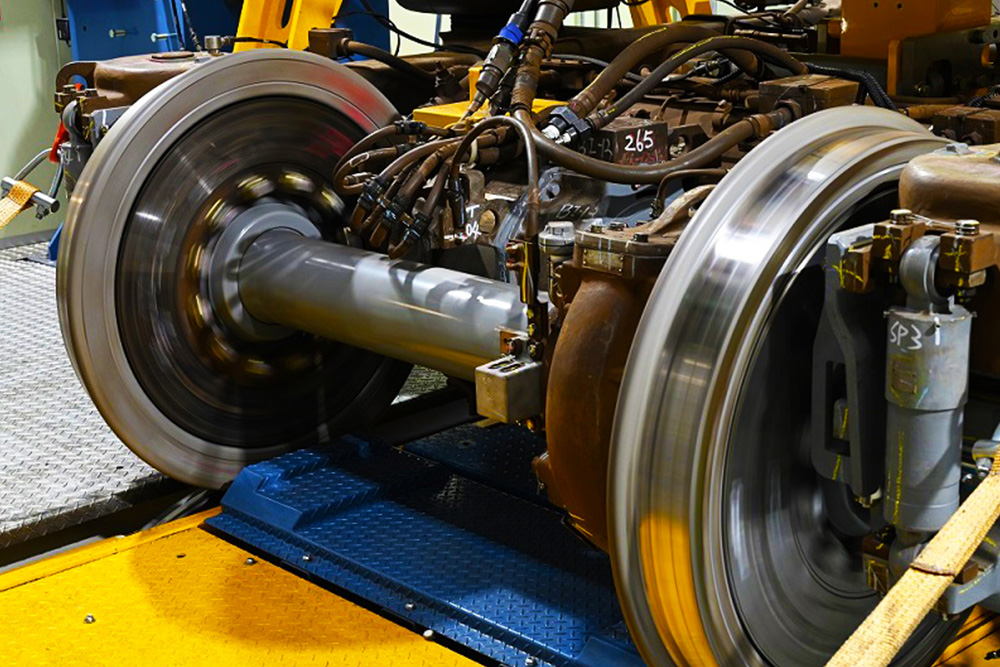

A bogie is a key component of railway vehicles especially for high speed trains. Attached underneath the train, the structure contains essential parts including traction motors, brakes, suspensions, and wheels, carrying the weight of the coach. It reduces vibration and is critical to the safety and stability of running trains, while bogies with motors also provide power for the train.

Conventionally, train bogies undergo regular inspections such as wheels, bearings, and axle verification and load testing to ensure their functionality and performance. The Bogie Running Tester (BRT) developed by ITRI and Taiwan High Speed Rail Corporation (THSRC) is now incorporated into existing maintenance procedures to enhance the quality and efficiency of bogies.

ITRI and THSRC’s BRT can test bogies running at speeds of up to 320 km/h. This high speed assessment helps improve the safety of mainline testing. Moreover, the system can detect and analyze bogie abnormalities at an early stage. With the establishment of the maintenance database, monitoring accuracy and system reliability are increased.

“The BRT leverages ITRI’s expertise in mechatronic systems, control engineering, vibration noise suppression, and system integration,” said Da-Jeng Yao, General Director of ITRI’s Mechanical and Mechatronics Systems Research Laboratories. He further indicated that the BRT collaboration between ITRI and THSRC has made Taiwan one of the few countries in the world with the ability to design a BRT. Other than Taiwan, only Japan, Germany, and China possess this technology.

The self-design and manufacturing of BRTs is conducive to railway industry localization and brings many benefits. Taiwan’s component makers, for example, can join to provide flexible customized services with add-on features. Moreover, costs will be saved when there is less dependence on international suppliers.

According to the European Rail Industry Association, the global rail market is estimated to grow up to 192 billion euros by 2023. ITRI and THSRC’s BRT aims at such opportunities and seeks to enable expansion into the Southeast Asian market.

The BRT has obtained the Conformité Européenne (CE) Certification with its performance proved in anti-electromagnetic interference, low voltage and mechanical safety. In addition to high speed rail, it can also be introduced to medium-speed rail to support safe transportation service.