Special Article Part 1

Global Trends of Enhancing Sustainability by ICT Products Senior Vice President Meng-Tsung Su, Chun-Hao Yueh, and Chia-Ying Chen

The United Nations Climate Change Conference (COP28), which concluded on December 13, 2023, reached an agreement by negotiators from 198 countries to commit to transitioning away from fossil fuels in energy systems and accelerating actions to achieve net zero before 2050. This is the first time in the history of the climate summit that the term “fossil fuels” was explicitly mentioned in the resolution. This resolution, however, did not include “phasing out fossil fuels” as expected by various European and American countries, but used a more neutral word “transitioning.” In addition, the resolution recognized that global carbon emissions will peak before 2025 and promised to phase out “inefficient fossil fuel subsidies.”

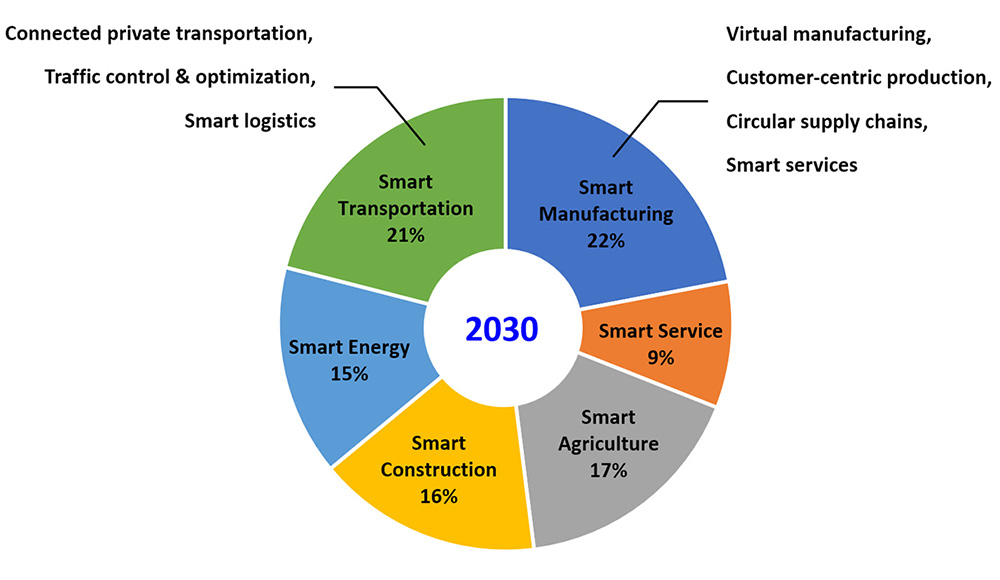

In pursuit of practical solutions, the Global Enabling Sustainability Initiative (GeSI) SMARTer2030 report projected that by 2030, information and communication technology (ICT) products could lead to a reduction of 1.25 billion tons of CO2e, equating to 1.97% of global emissions in various global industry sectors. The primary contributors to this reduction are identified in key sectors, with smart manufacturing leading the charge at 22%, followed closely by smart transportation (21%), smart agriculture (17%), smart construction (16%), and smart energy (15%), accounting for a total of 91%.

2030 ICT CO2e Abatement Potential by Use Case (GeSI, 2015).

As the frontrunner in carbon reduction, smart manufacturing encapsulates a multitude of critical applications for energy-saving opportunities:

- Virtual Manufacturing: This involves the fusion of cyber-physical systems (CPS) with the industrial internet of things (IIoT), and machine-to-machine (M2M) technologies to create digital twins of physical manufacturing and simulated manufacturing. This integration optimizes efficiency in production processes, enhances resource utilization, and reduces energy consumption for better sustainable industrial practices.

- Customer-Centric Production: Incorporating customer preferences into both the development and production phases, it fosters a tailored strategy that minimizes waste and optimizes energy usage. It also adopts decentralized production networks and distributed manufacturing models to increase energy efficiency by reducing transportation-related energy consumption.

- Circular Supply Chains: As a pivotal component in enhancing the sustainability of smart manufacturing, circular supply chains engage in practices such as remanufacturing products, components, and waste, as well as adopting circular packaging. This not only reduces the overall demand for new resources but also minimizes the environmental footprint typically associated with the disposal of manufacturing by-products.

- Smart Services: These services help create a cross-sector ecosystem that seamlessly integrates both upstream and downstream manufacturing processes. The interconnected services enhance operational efficiency, reduce energy-intensive tasks, and contribute to a more sustainable and interconnected smart manufacturing environment.