Special Article Part 2

Contribution to Sustainability by Taiwan Semiconductor Industry

The EU’s Carbon Border Adjustment Mechanism (CBAM) serves as a strategic tool by imposing a “carbon price” on imports of high-carbon-intensity items. This compels product companies and their upstream/downstream suppliers to work together for emission reduction of their products and manufacturing processes. The long-term strategic goal for CBAM is to realize a 55% reduction in EU industries’ CO2 emissions between 1990 and 2030.

Initially, CBAM will mainly apply to steel and other industrial goods such as iron, aluminum, fertilizers, ammonia, and cement imported into the EU starting in 2027. Although semiconductors are not among the initial list of high-carbon-intensity items, due to semiconductor manufacturing’s nature of high energy consumption, the increasing pressure for the semiconductor industry to reduce energy consumption and enhance sustainability in the near future should not be underestimated.

The semiconductor industry in Taiwan holds a prominent position, not only for its significant economic contributions but also due to the attention it draws regarding carbon emissions and electricity consumption. In 2021, the top 10 carbon-emitting companies accounted for 39% (about 107 million metric tons). These companies include electricity, petrochemical, steel, plastic, cement, and semiconductor industries. The semiconductor industry, known for its advanced chip manufacturing processes with high value but requiring higher electricity consumption and carbon emissions, often becomes the focus of attention from media and environmental groups.

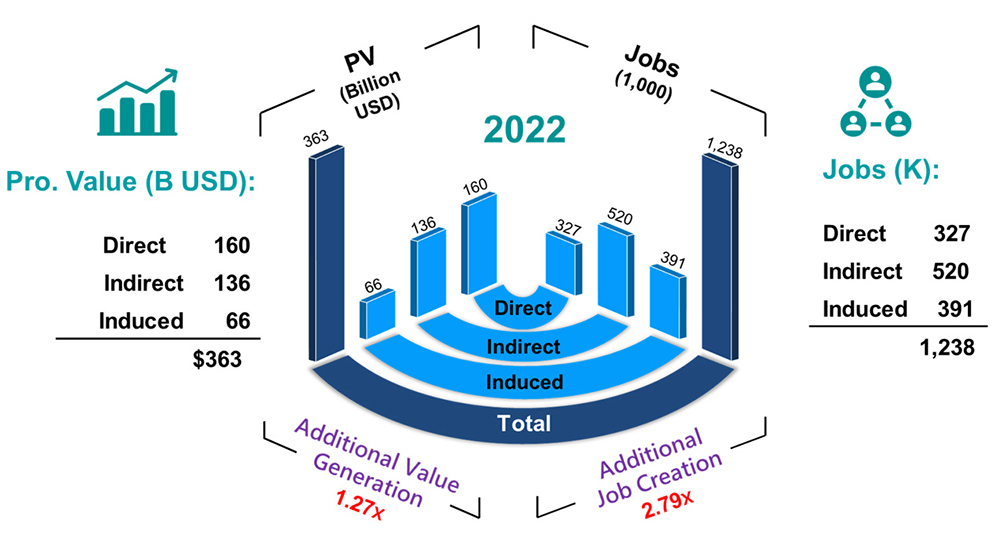

The high value of Taiwan’s semiconductor industry can be demonstrated by a research study of the Industry, Science and Technology International Strategy Center (ISTI) of ITRI. In 2022, the semiconductor industry in Taiwan reached US$ 160 billion in revenues with employment of 327,000 people. When the additional outputs based on supply chain industries (indirect) and disposable income used in related service industries (induced) are included, the semiconductor industry also generated an additional 127% in revenues and 279% in employment.

Total Revenues and Employment Generated by Taiwan’s Semiconductor Industry (IEK Consulting, 2024).

According to another study (2021) conducted by ISTI of ITRI, the semiconductor industry in Taiwan has demonstrated strong performance in electricity consumption competitiveness, an index defined by the ratio of “an industry’s total value added” to “its total electricity consumption.” Compared to other industry sectors in Taiwan, the semiconductor industry created a value of 26.8%, higher than the overall manufacturing industry (NTD 59.7 value-add per kWh vs. NTD 47.1).

Despite already surpassing the overall average within Taiwan, the electricity consumption competitiveness of the semiconductor industry can still be improved in three key directions: (1) vertical integration of advanced wafer manufacturing, packaging, and testing to increase added value; (2) product efficiency review to assess power efficiency from a product perspective and phase out of inefficient products; (3) global presence expansion by strategically planning investments and establishing facilities to leverage complementary technology, materials, and talent outside Taiwan.

According to another study by ISTI of ITRI, ICT products with embedded semiconductors manufactured by TSMC and used in AI computing, 5G, HPC, among others, are estimated to currently contribute to global energy savings of over 200 billion kWh by 2030, roughly more than four times the electricity consumption for production. In other words, for every kWh of electricity used in production by TSMC in Taiwan, its IC products can be used in smart electronic products or services to save 4 kWh of electricity globally. With advantages in chip market share, computing speed, and expanded application scope, there is a future trend of increasing energy-saving benefits year by year.

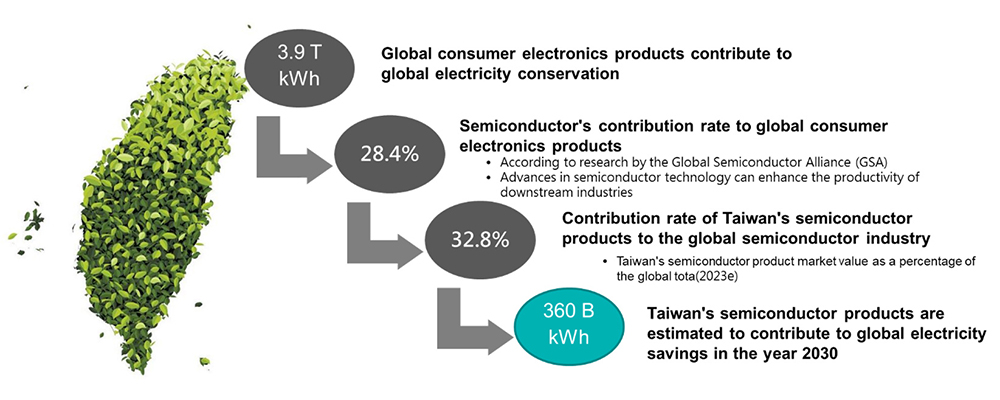

Furthermore, still another study by ISTI of ITRI adopted the simulation models from the American Council for an Energy-Efficient Economy (ACEEE) for different scenarios of energy-saving effects based on the use of electronic products with embedded semiconductors. The results indicated that by 2030, the global ICT products could save approximately 11.8% of the world’s total electricity consumption (3.9 trillion kWh). Within the ICT products, the contribution by global semiconductors will be about 28.4%. Considering that the semiconductors produced by Taiwan account for 32.8%, Taiwan’s semiconductor industry could help reduce the world’s total electricity consumption by about 360 billion kWh, representing 1.1% of the global total electricity consumption.

Taiwan’s Semiconductor Industry Contributes to Global Electricity Saving (IEK Consulting, 2024).

Of the 360 billion kWh saving by 2030, Taiwan’s semiconductor products are expected to make an even more significant impact on global energy saving, contributing to an estimated saving of 22% (80 billion kWh) from smart manufacturing. ICT products with embedded semiconductors can enable smart manufacturing applications in cyber-physical systems (CPS), industrial internet of things (IIoT), embedded system production technology, data analytics and cloud computing, 3-D printing, as well as drones and robotics.

Also, from smart transportation, Taiwan’s semiconductor products are expected to assist in global energy savings of 21% (76 billion kWh) by 2030. Energy-saving benefits include traffic control and optimization (e.g. automated driving, autonomous vehicles, driverless cars), connected private transportation (e.g. car/route sharing, intermodal transport), and smart logistics (e.g. fleet management and optimized routes, digital warehouses, operational agility).

Although the semiconductor industry in Taiwan faces environmental concerns for its carbon emissions and electricity consumption, its electricity consumption competitiveness outperforms other manufacturing sectors. Moreover, products manufactured by TSMC are expected to contribute to a significant impact on global energy savings, including an estimated total of 43% from smart manufacturing and smart transportation. This underscores the potential positive impact of Taiwan's semiconductor products on global energy efficiency in the coming years.

Regarding global policies, there is a critical concern related to the EU’s 2050 net-zero emissions goal and CBAM. The mechanism’s imposition of carbon price on Scope 3, which includes suppliers, distributors, and product use of imported products to the EU, raises potential challenges. For example, the semiconductor industry in Taiwan, currently manufacturing and assembling products or modules locally before exporting to brand companies overseas, may face additional financial and societal burdens due to CBAM’s carbon levies. There is a call for recognizing the benefits of ICT products with embedded semiconductors in reducing carbon emissions and electricity consumption through carbon credits or reduced carbon prices. The suggestion is that, similar to industries like Tesla in the sustainability sector, semiconductor contributions to enhancing sustainability should be acknowledged, and ICT products and their suppliers should receive proportional carbon credits for their positive environmental impact.