Activity

Advanced Semiconductor Techs at SEMICON Taiwan

At the 2024 SEMICON Taiwan, the world’s most influential semiconductor exhibition, ITRI showcased 45 cutting-edge technologies in three major themes: intelligent systems, compound semiconductors, and high-performance computing. Highlight technologies include an intelligent wafer grinding system, an automotive silicon carbide (SiC) solution, and a high-end chip cooling solution for AI servers.

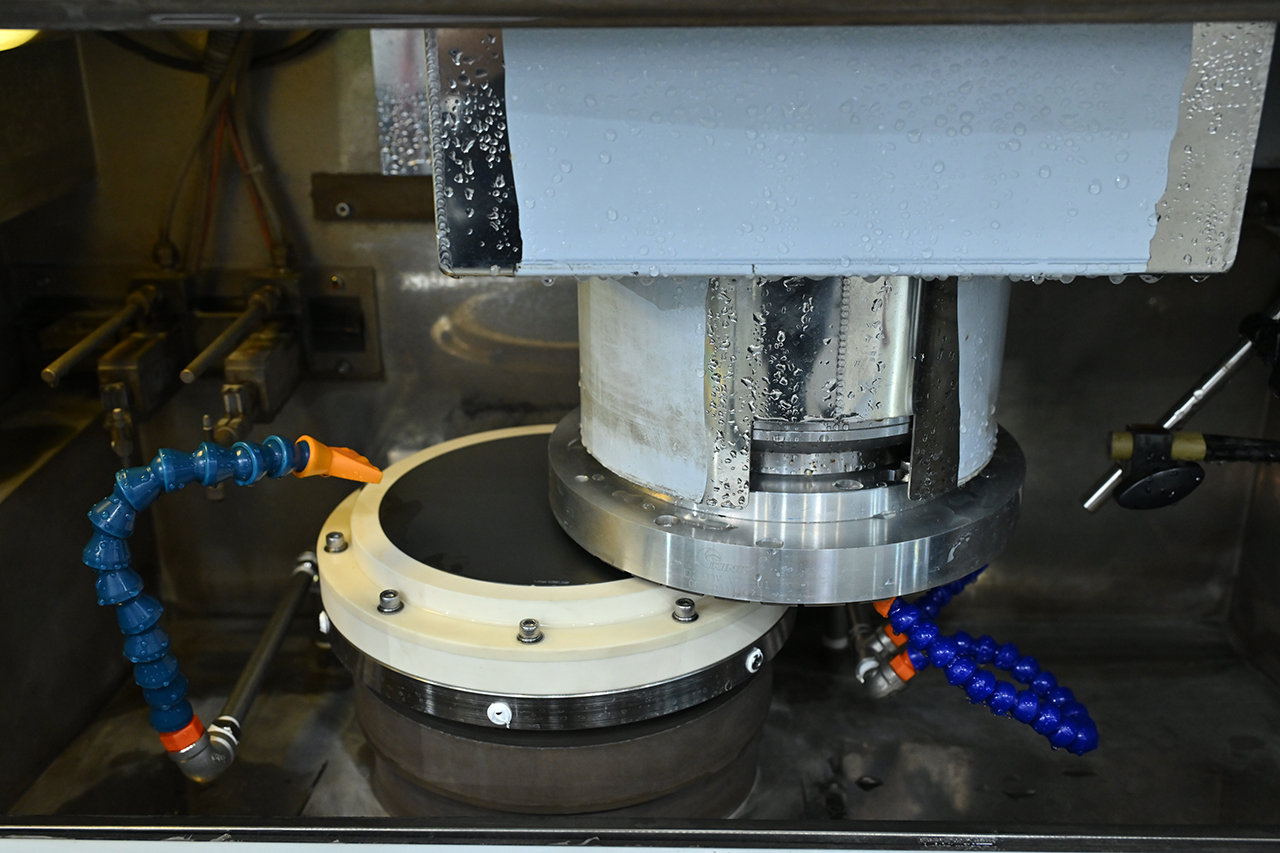

Intelligent Wafer Grinding System

SiC is a key material for high-power automotive electronics; however, its hard and brittle properties make processing difficult, affecting production efficiency and costs. ITRI has developed an intelligent wafer grinding system that analyzes the state of the grinding wheel in real time to detect clogging and dulling. Equipped with a smart ultrasonic spindle, the system shakes off grinding dust and keeps cutting tools sharp, which can reduce downtime for replacing consumables. It has been verified to improve SiC processing efficiency by three to five times and lower maintenance costs compared to conventional grinding methods.

ITRI’s intelligent wafer grinding system enhances SiC processing efficiency.

Automotive SiC Solution

Featuring high voltage, high current, and low power consumption, SiC power semiconductor technology has been increasingly deployed for electric vehicles (EVs). ITRI has developed a comprehensive, efficient automotive SiC solution for EV applications including SiC power components and modules, motor drives, onboard chargers, and charging piles. It showcased a 250 kW EV powertrain traction inverter utilizing its low-thermal-resistant 1.7 kV SiC power device and the optimized three-phase power module. The 22 kW onboard charger and charging pile also integrate ITRI’s 1.7 kV power module. By transferring these SiC solutions to component manufacturing and system providers, ITRI aims to accelerate the development of the SiC power semiconductor industry and align with global market trends.

ITRI offers a comprehensive automotive SiC solution that aids the development of the SiC power semiconductor industry.

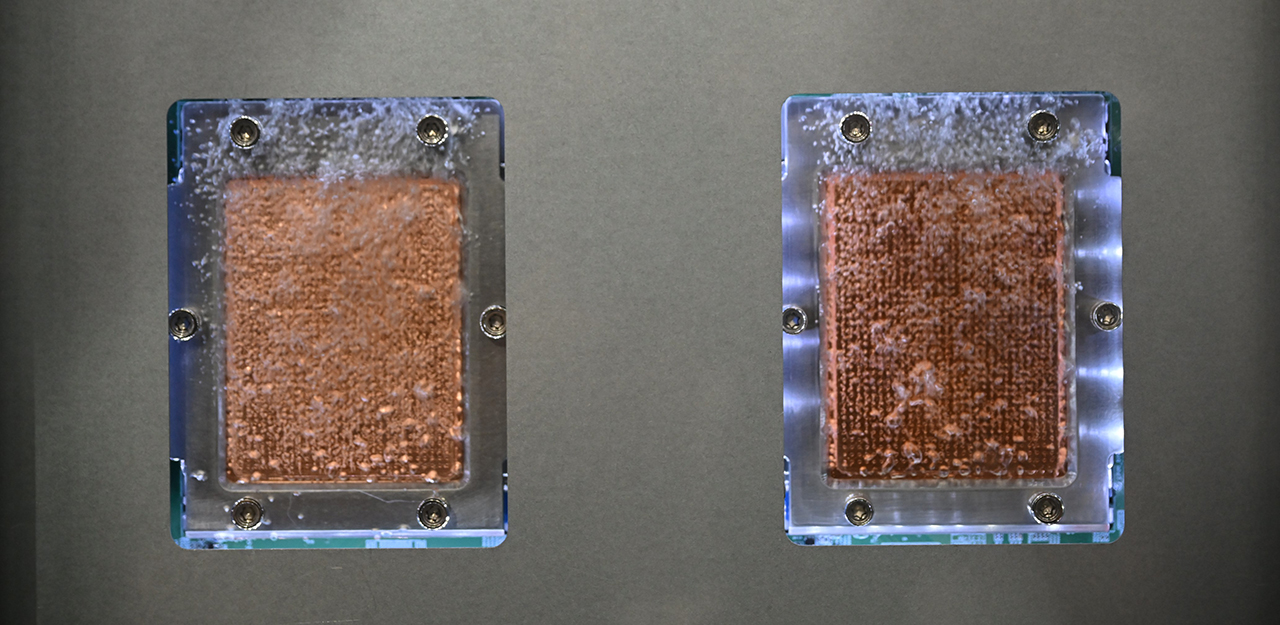

High-End Chip Cooling Solution for AI Servers

High-end AI chips can generate heat up to 1,000 watts. However, the heat dissipation capability of conventional air cooling modules is limited to only 750 watts. As a result, liquid cooling technology is increasingly becoming popular for high-end AI chips. To enhance immersion cooling, ITRI has developed a vapor chamber boiler (VC boiler) and attached it directly to the chip. With its high thermal uniformity and microstructures on the surface, the VC boiler can effectively remove heat through rapid evaporation within the chip. In collaboration with leading manufacturers, ITRI has successfully integrated the supply chain of AI chip production, helping industry players make an entry into the AI server cooling market.

ITRI has developed a VC boiler technology to enhance chip cooling for AI servers.

During the exhibition, Dr. Shih-Chieh Chang, General Director of Electronic and Optoelectronic System Research Laboratories at ITRI, noted that AI will drive future industrial transformation and economic development. “In particular, the emergence of generative AI has accelerated the shift from cloud computing to edge computing. It is also reshaping applications in consumer electronics and smart homes,” he said.

ITRI, in response to the global trend for AI, is actively dedicated to the R&D of advanced semiconductor technologies. While driving innovations in chip design and manufacturing, it focuses on market needs and ensures that Taiwan remains a leader in this field.