R&D Story

The AI Chip That Sips Power, Not Gulps It

Artificial intelligence continues to spread—into our phones, factories, and soon, perhaps, our toasters. But here’s the catch: while AI gets smarter, the devices running it often get hungrier and slower. Edge devices that perform local AI computations, such as drones, robots, and sensors, tend to burn through both power and patience.

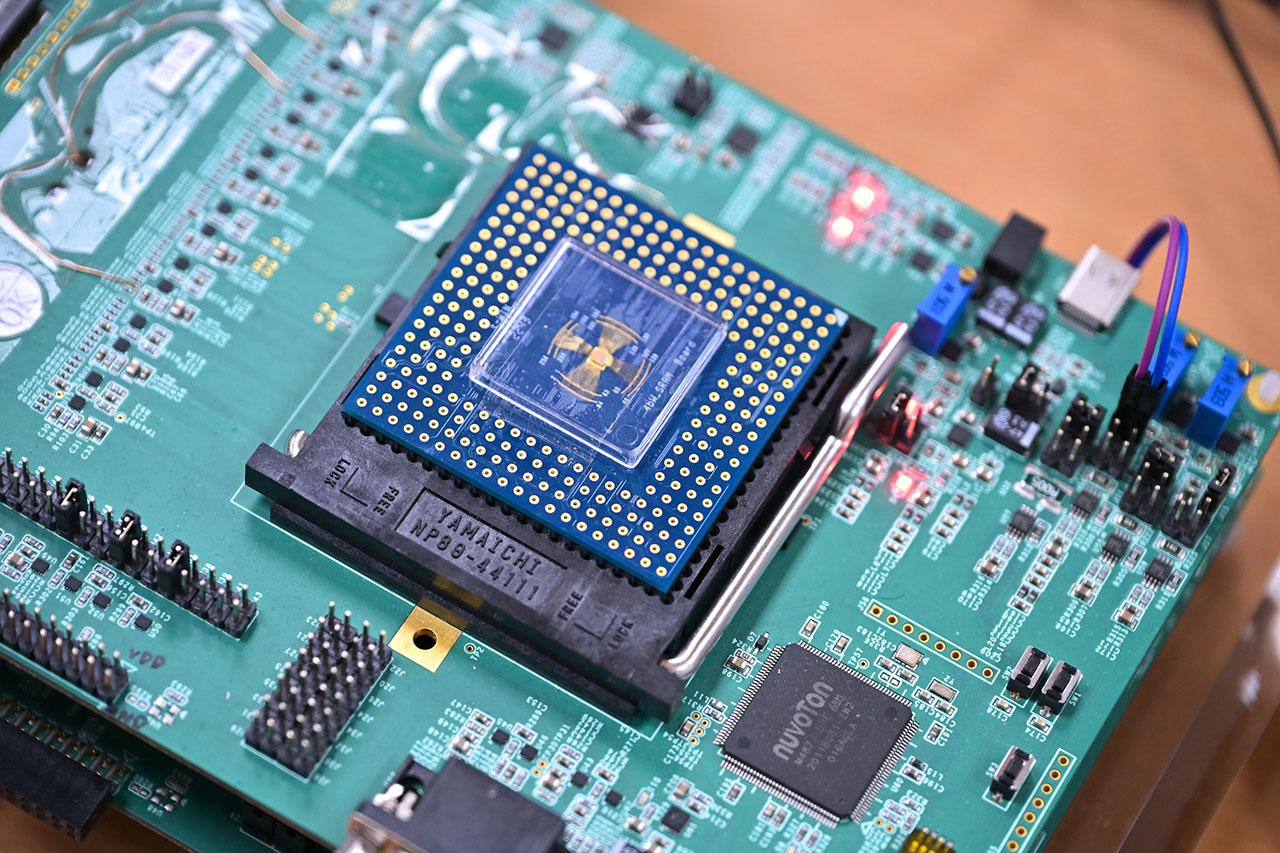

That’s where ITRI’s latest breakthrough steps in. By fusing its own AI models with a custom-built circuit design, ITRI has created a chip that’s over 10 times more power-efficient than conventional ones. Officially named the Next-Generation Computing Architecture for Ultra-Low-Power Edge Recognition, this technology lets AI tasks that once required the cloud or a power-hungry server run smoothly on a chip no bigger than your fingertip.

“What other AI chips can’t do, this architecture makes possible,” said Shyh-Shyuan Sheu, Division Director at ITRI’s Electronic and Optoelectronic System Research Laboratories, with a grin that suggested he meant it.

ITRI created an AI chip that cut power consumption by over tenfold, paving the way for widespread edge AI applications.

Thinking Inside the Memory

The magic lies in something called Computing-in-Memory (CIM), a simple idea that upends decades of computing tradition. Normally, a processor and a memory spend their lives tossing data back and forth like an overworked courier service, wasting time and energy with every trip. CIM breaks that routine by doing the math right where the data lives. Fewer commutes, less energy, happier electrons.

To make CIM practical, stable, and efficient enough for the real world, the team reimagined both its hardware and software structures. On the hardware side, they cut the operating voltage from the usual 1–1.2 volts down to a frugal 0.4 volts or less, slashing power draw. “The challenge,” said Sih-Han Li, Deputy R&D Director at ITRI’s Electronic and Optoelectronic System Research Laboratories, “is that when you go that low, the circuit’s sense of balance starts to slip. Without special protection, the results can go haywire.”

To keep the system steady, the team devised an anti-offset mechanism—a kind of gyroscope for electrons, keeping the calculations upright, even when the voltage floor tilts.

Meanwhile, on the software front, the team went after the biggest power hogs in AI computation: the matrix multiply-accumulate (MAC) operations. These workhorses eat up as much as 70–80% of the total workload. The team put the focus on the heavy lifting at the high-intensity neural network (NN) layers and trimmed the preprocessing steps, pushing efficiency to the next level. On top of that, by tailoring data precision to actual needs—a process they call “task equivalence”—they managed to lighten the load without losing smarts.

“A robot doesn’t need to admire the color of an apple,” Sheu joked. “It just needs to know it’s an apple.”

That kind of selective attention keeps the AI nimble and light on its computational feet. Even better, the chip can scale its operations up or down depending on the task, whether it’s a simple sensor job or heavy-duty image analysis.

CIM technology enables longer operation, greater performance, and ultra-low power use, all in one tiny package.

Record-Breaking Efficiency

After countless tweaks and tests by a 20-member team of hardware and software experts, the chip didn’t just meet expectations—it shattered them. In 1-bit mode, it achieves a world-record 20,943 tera-operations per watt (TOPS/W), leaving the global average of around 1,000 TOPS/W in the dust.

“Plenty of chips claim low-voltage operation,” Sheu noted, “but integrating that into CIM and breaking a world record? That’s a first.”

This technology has already been tested with semiconductor and smart sensor companies, successfully completing low-power voice and image verification. ITRI plans to begin with niche markets such as smart manufacturing, energy monitoring, and medical wearables, helping partners turn the technology into products with serious commercial muscle.

A Power Saver for a Power-Hungry Future

So what comes next? According to Sheu, robots and drones are first in line. “Imagine every home having a robot helper,” he said. “Each one could have hundreds of sensors, and each sensor will need its own tiny AI brain.”

That’s where this chip’s blend of energy efficiency and flexibility really shines. Built to keep tomorrow’s smart machines running longer, thinking faster, and wasting less, ITRI’s innovation may well be the quiet powerhouse behind the next wave of intelligent devices.