Feature

Revolutionize Textile Recycling with Circu-Texfilm

The textile industry faces a monumental waste challenge, with only about 1% of discarded clothing being recycled back into new garments. Driven by escalating demand for recycled materials and strict new regulations, such as the EU's push for mandatory separate collection and Extended Producer Responsibility policies, solutions are desperately needed.

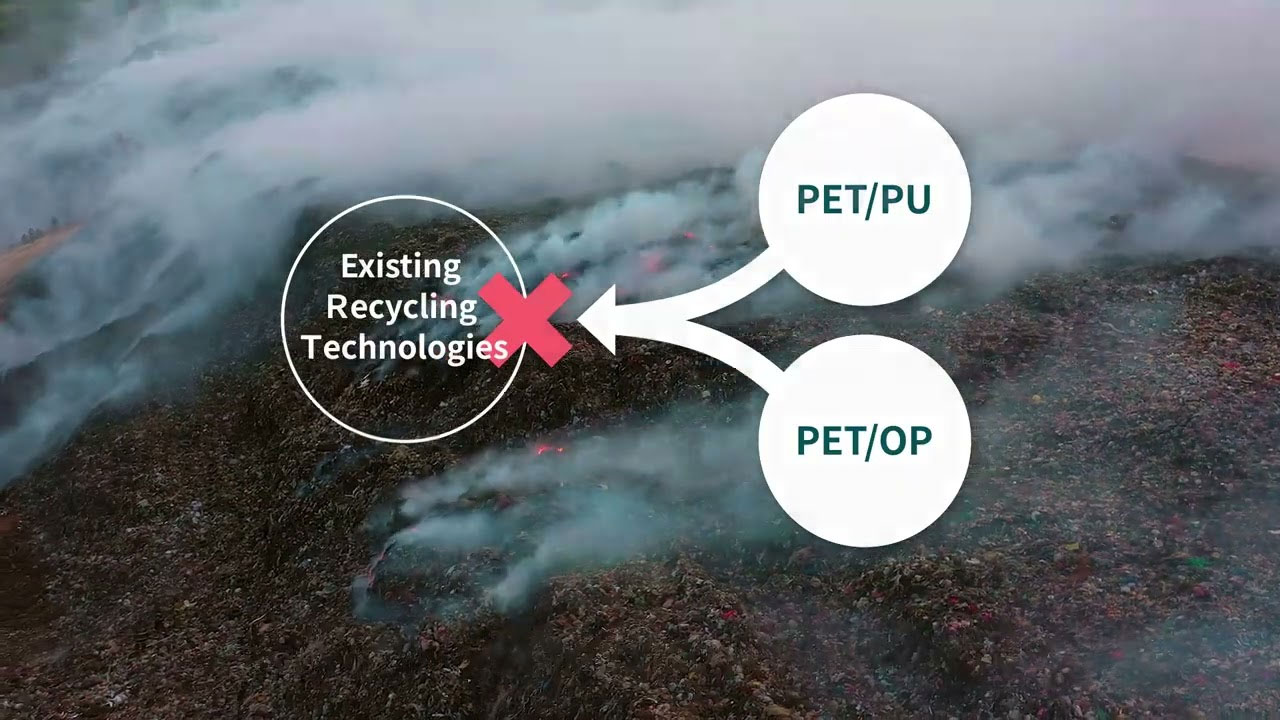

Circu-Texfilm is a patented, game-changing textile-to-textile recycling system. Developed by ITRI and SINGTEX, it directly tackles the previously unrecyclable composite textiles—specifically PET/PU and PET/OP blends common in performance wear. This technology significantly boosts the recycling rate of valuable polyester from complex waste.

Traditional recycling focuses narrowly on single-material fabrics or rPET from plastic bottles. Circu-Texfilm’s innovation lies in its chemical depolymerization and PU polymerization process. This method transforms the mixed-material waste into a high-quality, waterproof, and breathable polyurethane (PU) film.

Circu-Texfilm targets previously unrecyclable composite PET/PU and PET/OP textiles.

The process converts the textile waste into a functional polyol, a key component for PU synthesis. Crucially, the technology uses a structural design to balance the hydrophobic and hydrophilic properties of the recycled materials, overcoming the issue of traditional rPET-derived polyol being highly crystalline and water-repellent. The result is a low-crystallinity, high-flowability polyol that yields superior PU resin. This efficient process can even utilize mixed-color textile waste without pre-decolorization, making it cost-effective and suitable for producing darker-colored films perfect for technical garments.

The global market for functional films is booming, projected to grow at a 5.9% CAGR through 2030. Circu-Texfilm is positioned to capitalize on this, producing resin that is highly customizable to meet demanding performance specifications. The final films meet bluesign® and Oeko-Tex environmental standards, ensuring they are fit for high-end applications like furniture, footwear, and protective gear, in addition to apparel.

By providing a viable, high-efficiency method for recycling complex PET blends, Circu-Texfilm has the potential to dramatically increase the recovery of textile waste. With polyester comprising up to 30% of the US clothing market, the potential reduction in landfill burden is immense. This technology reinforces a simple truth: what we recycle becomes resources, not waste—a critical step forward in achieving a truly sustainable, closed-loop fashion economy.