Feature

AI-WaJe™ for High-Value Tire Recycling

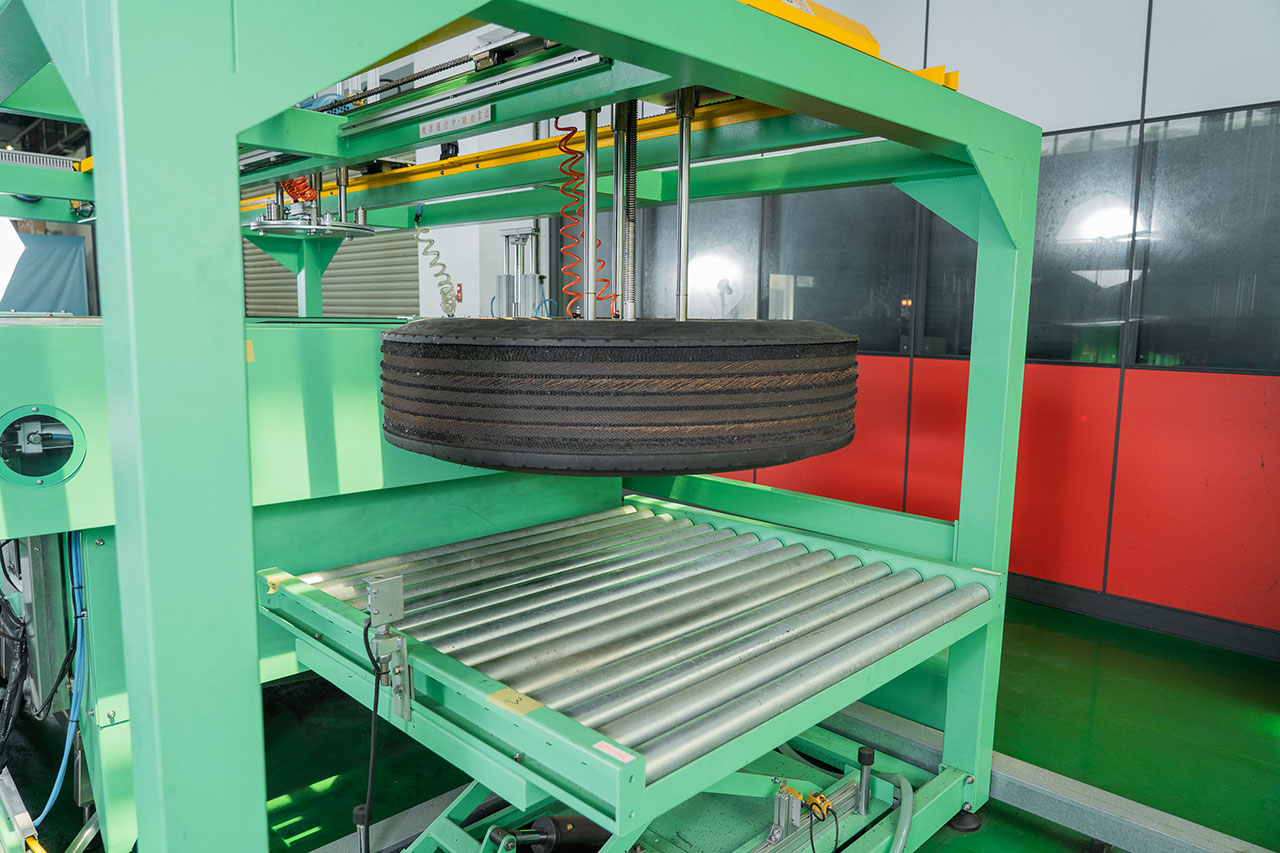

The AI-WaJe™ system represents a breakthrough in sustainable tire recycling, addressing the global challenge of end-of-life tires through an AI-optimized, non-thermal water jet process that transforms waste tires into high-activity rubber powder. Unlike conventional mechanical or pyrolytic methods, AI-WaJe™ leverages molecular-level thermal-energy conversion to selectively break down excessively cross-linked rubber molecules, thereby restoring their chemical reactivity and enabling reuse in high-performance applications.

AI-WaJe™ efficiently recycles end-of-life tires into high-activity reusable rubber powder.

Superior Efficiency & Material Quality

AI-WaJe™ achieves remarkable productivity and material performance. It can process a large truck tire in just six minutes, compared with more than an hour using traditional mechanical methods. The process produces rubber powder with a verified relative activity of up to 79%, enabling direct reintegration into new tire formulations and other premium polymer products.

Sustainability & Carbon Reduction

Beyond industrial performance, AI-WaJe™ delivers significant environmental benefits. Its carbon footprint of 370 g CO₂/kg is approximately 45% lower than that of pyrolysis (672 g CO₂/kg), which relies on high-temperature decomposition. This substantial reduction underscores AI-WaJe™’s contribution to global carbon neutrality and circular manufacturing goals.

AI-Driven Precision & Reliability

At the heart of the system lies the Smart Water Jet Expert System, which resolves the long-standing issue of inconsistent quality in water jet recycling. Drawing from a comprehensive operational dataset—including pressure, flow rate, feed speed, and corresponding activity outcomes—the AI model employs regression learning to instantly determine and apply optimal parameter combinations. This closed-loop control ensures stable production with 95% predictive accuracy, far surpassing the 20–30% activity levels typically achieved by competing methods.

High-Value Applications & Global Impact

The resulting high-activity rubber powder meets or exceeds the quality standards of leading tire manufacturers such as Michelin, Continental, and Bridgestone, all of which require relative activity above 43%. ITRI’s spinoff, Taiwan Polymer Material Company, aims to commercialize this technology for new tire manufacturing, automotive plastics, green building materials, and advanced polymer composites, while exporting turnkey AI-WaJe™ production systems to accelerate sustainable tire recycling worldwide.